The New Carbon….Carbon Steel!

What’s lighter than a modern carbon bike? The new 13.5 pound Rodriguez Outlaw

This morning, I dropped my old truck off for repairs, and pulled my bike out of the back to ride on in to work. The mechanic was impressed with the nice paint job. It’s always fun to have someone lift my Rodriguez S3 bike and watch their jaw drop as they effortlessly lift it chest high with just one hand. So, I handed the bike over to him and said “Lift it up”.

Well, he lifted it, and as expected, his jaw did drop. He said “I gotta show this to the other guys!” So he rolled it to the back of the shop, lifting it several more times in disbelief as he went. Once there, he handed it to the other mechanics and told them to lift it up. Needless to say, they had the same reaction as he did. I asked them all “What do you think the bike is made of?” They all said in unison “Carbon fiber…”….then, noticing that I was shaking my head ‘no’ one of them said “Titanium?” “No” I said. “This is an American made steel bike, made right here in Seattle”. The surprise on their faces was evident as they all lifted the bike several more times, and one of them even took out his magnetic ‘pick-up’ pen device and stuck it right to the top tube just to make sure it was steel.

If you ask most people why they bought a carbon fiber bike, the answer invariably comes back “Carbon bikes are lighter weight”. Well, what if that’s not true? What if that’s just something you’ve been told? What if a comparably priced steel bike was just as light as a carbon fiber bike? Would you still want a carbon bike? Now, what if a comparably priced steel bike was even lighter than the carbon bike? How about one step further…what if a steel bike was lighter, less expensive and rode faster?

Think I’m crazy? Let’s peel the layers off of the onion and get to the truth about carbon fiber mania. The fact is, here at Rodriguez we did make carbon fiber bikes, but that was 35 years ago. Yes, you read right. 35 years ago we made custom carbon fiber bikes. I’ve written a slew of info about frame materials here if you are having trouble sleeping. Material World is a 4 part article that I wrote for the Bicycle Paper a while back.

Before we start: Is weight the only consideration for spending a lot of money on a bicycle? How about fit, durability, color, ride quality or longevity? Do these matter to you at all? If so, you’ll want to read on. If weight’s the only thing important to you, then you should read on as well, because I think you’ll be surprised.

Along for the Ride

We can start with the premise that most people prefer the ride quality of a steel frame to carbon. Heck, even a lot of carbon bike manufacturers cede the argument to steel for durability and ride quality. So what if you could pay less money, have a faster riding bike, more comfortable frame, and still have the lightest bike in the crowd? Sounds to good to be true right? Well, I’m actually talking about our 13.5 pound 2013 Rodriguez Outlaw, and it’s very real! As a matter of fact we’ve converted dozens of carbon frame riders to the Outlaw by just allowing a test ride on this amazing bike! Even the most die-hard carbon enthusiast will have to admit this bike cannot be beat.

I have had several people tell me they have a friend with a lighter bike than the Outlaw, but have yet to weigh one. The closest carbon bike to come in here was still 2 ounces heavier than the Outlaw, but was twice the price. Seeing is believing. We keep a scale at our front desk so that we can weigh bikes that come in, and we’ve weighed just about everything. Don’t trust word of mouth as our industry is full of….well….inaccuracy at best when it comes to weights. I know that a lot of manufacturers publish weights in their catalogs and websites that are untrue. If you want to have some fun, buy a small digital scale and carry around with you to bike shops. Ask what a bike weighs, and then pull out the scale to verify it. I’ve done it, and it’s a blast! Like to read more about that?

All right, all right, back to business

I know, I know….you’re reading all of this, but then you pick up a magazine and read a glowing review of a sweet carbon fiber bike from some giant company. How can that be? Wouldn’t they be reviewing steel bikes if steel was so cool?

Let’s have a look at the vicious ‘Cycle of Business’ shall we?

Magazines review bicycles that their advertisers send to them for review. Companies send bikes for review that they want to sell. Look through the magazine and you’ll usually find an advertisement for the very bike that got that glowing review…..sometimes just opposite the review itself. It’s no coincidence. Big companies that advertise don’t make hand-built steel bikes. That’s because carbon fiber bikes are inexpensive to build overseas, so it would make sense to prime the public to want them. Not to say that the review isn’t genuine. The reviewer probably really liked the bike. It’s just that the opportunity to ride that bike for review is not a random selection, but a selection from an advertiser. The Cycle Continues

“Well, what about the pros?” you ask. “The pros only ride the best right? Almost all the pros ride carbon fiber, so doesn’t that make it the best?” Right and wrong. You see, the pros don’t ride a bike that they expect to last year after year (durability). Heck, a lot of them don’t even require their frame and fork to last one race. So, if by ‘best’ you include durability in your criteria, a pro has no need for that.

A pro does have a need for sponsorship though, and if their sponsor is trying to sell carbon fiber frames, then carbon fiber they will ride. After all, it’s their job to sell bikes. If we paid millions in sponsorship to a pro team, then they would be thrilled to ride steel Rodriguez Outlaw hand-built bikes (but, that’s not going to happen). If your criteria is “I ride what I’m paid the most $$ to ride” then at this point in history, carbon is the best. I’m not saying that a carbon frame will not perform, I’m just saying that it is not a superior performance to steel.

Fit note: – Realize also that the pros are riding bicycle geometries designed to fit them and their riding style. When you purchase that same frame in a store, you’re not purchasing a bike to fit you, but rather a bike to fit the pro it was made for. Ask your sales person what it would cost to get that same frame made truly custom to fit your body and riding style.

What’s fashion got to do with it? With all of the magazine ads, pro sponsorships, certain bike shops, and even industry rags smack-talking any bike that isn’t carbon, it’s almost fashionable to ride carbon fiber. I’d say that it’s become so fashionable in some circles that you almost have to be a heretic to ride steel. One more great reason that we call this bike the Outlaw I say. Peer pressure is a powerful motivator, but we’re here to help give you the ammunition to resist…..come to the dark side……be an Outlaw….like Alice Cooper says, Flush the Fashion!

This ‘cycle’ of promotion steers the consumer to the product the manufacturers wants to sell. Now, obviously I’m trying to do the same thing, but I’m willing to put my money where my mouth is. Basically, you’ve got to verify weight if it’s important to you. I think that if you do that, you’ll find that here at Rodriguez, we can build your bike in America just as light as any overseas carbon bike. I’m confident that if you ride our bike back to back with a carbon bike, you’ll choose the Rodriguez every time….just like Steve and countless others have over last few years.

With the fashion sufficiently flushed, let’s get down to earth

I think that I’ve shown here that a light weight bicycle can be achieved through either material, so I would like to put all the hype about weight aside for minute, and talk about some things that are way more important.

1.) Fit: If your bicycle doesn’t fit well, you’re going to hate riding it no matter what it’s made out of. At Rodriguez we view fit as the most important component to any bicycle. We offer a fit guarantee with every bicycle we sell. Here’s a few articles that I’ve written over the years to back-up what I’m talking about on this subject. Ignoring fit when buying your bicycle is a huge mistake that many people make.

2.) Longevity: If you don’t care how long your new bike will last, then don’t worry about this section.

Most of our customers plan to ride their new Rodriguez for many years to come. What the consumer doesn’t realize is that our industry is steering very heavily toward a disposable product model by engineering bicycles to only last 5 to 10 years. Sure, carbon fiber frames with their short warranties are part of that model, but an even greater problem is wreaking havoc at bicycle repair shops all around the country. This is the trend of straying from industry standards to proprietary parts.

What the heck am I talking about? If you don’t know what ISO standards are, and proprietary parts are, you’re bound to end up on a bicycle that will end up in a land fill before its time. Yes, I’ve written a few things on the subject.

Here at Rodriguez, we reject the disposable bike philosophy, and substitute our own. A Rodriguez is built to be a forever bike.

3.) Personality: Do you have a favorite color? Why not paint your bike that color? At Rodriguez, your bike isn’t built until you order it, so you can choose any color you want. Obviously this isn’t a benefit exactly of a steel frame only, but Rodriguez customers love to have their new steed reflect their personality.

4.) Made in USA: I think there is something to be said for purchasing your bicycle from a company that is committed to manufacturing their products right here in the USA. We’ve seen almost every manufacturer move their production overseas in the last 2 decades in search of those creamy profits at the top. At Rodriguez, we’ve changed our manufacturing methods to provide the

greatest value and made in USA quality. We even manufacture parts in Seattle that we ship to Taiwan companies. How many manufacturers can say that?

The fact the we make your bike right here, means that we can customize more than just the paint. We can change geometry, braze-on fittings, tubing weights, wheel color, tires, you name it, we can do it!

5.) Most importantly: Don’t buy a bike, buy a shop! Really, it’s not about the bike. I can’t stress enough how important your relationship to your shop will be for your cycling enjoyment. A good shop has mature, professional employees who spend an hour or more fitting you to a bicycle before they sell you something. You should get a fit/comfort guarantee with your bicycle as well. Can you bring it back for a refund if you don’t like it? This is important, right?

6.) Get a Guarantee!! I cannot believe how many people have expensive bikes that are only a few weeks old and they hate them (like Jane). Why don’t they get their money back? Well, the shop or manufacturer doesn’t offer a satisfaction guarantee. Realize, any bike can be comfortable on a 10 minute test ride. The real test is how you feel on it after a few weeks. That gives you time to really settle in to the fit that your fitting professional has recommended, and feel how the bike reacts to your daily riding style. If the shop, or bicycle manufacturer, you’re working with doesn’t offer free fitting (including free stem and bar swaps) for their bicycle customers after the sale, I would strongly consider another shop. A lot of shops do not offer such a guarantee, so it’s your job as a consumer to ask that question before you purchase.

If they don’t offer a 30 day money back satisfaction guarantee, then realize that you will possibly be paying hundreds of dollars for fit work at another shop in order to relieve your pains, or, like Jane, you’ll just ride your old bike and let the new one hang in the garage. Now-a-days, high quality bicycles sell for $3,000, $6,000, $10,000 or more! That’s a lot of dinero for a wall hanger!

Wow! That’s a lot huh? If you’re looking for an uber-light bike, a heavy duty commuter, or and all-around bike for any occasion, we’d love to have a shot at becoming your bicycle company. Here at Rodriguez, we realize that the most important choice you make when selecting your new ride is the people that you are working with.

Thanks for reading

Dan

Articles linked in this post

- Rodriguez Outlaw

- Material World

- The Perfect Blend

- Steel, the miracle material

- Weight-a-Minute….

- Weighing the Truth

- Another Convert

- Just Your Size

- Our 40 year Fitting History

- Fit to Finish

- Pioneers and Profits

- Chaos, the new bicycle standard

- Proprietary Parts Explained

- Integrated Headsets

- Vest Value in the Industry

- Made in USA

- The Bushnell Eccentric

- Satisfaction Guarantee

If the Shoe Fits, will your Frame Fit too?

I’m 6′ tall, what size shoes should I buy?

Would you order shoes this way? Of course not. You know that 2 random people that are 6′ tall are very unlikely to wear the exact same shoe size. It would be ridiculous for a salesperson to even ask your height in determining a good shoe size for you, right? Maybe they can get a general sense…..6′ tall…male…..probably between size 9 and size 13, but nothing really accurate, and certainly not worth paying $100 or more for the guess. Obviously, you would want them to consider the size and width of your foot. Really good shoe stores will consider your ankle width, and maybe your arch. So that’s 4 measurements that count, and none of those measurements are your height.

How does this scenario relate to a bicycle?

Now you go online to consider a new bicycle, and the company is suggesting a size based on your height. How does that work? The answer: It doesn’t work. Your chances of getting the right bike size this way are about the same as getting the right shoe size that way. As a result, thousands of people each year pay good money to buy poorly fitting bikes. Then, they either ride uncomfortably, or even worse, hang the bike in the garage and decide that bike riding is not for them. So, I think we’ve determined that you don’t want to order shoes based on just your height, and maybe ordering an expensive bike that way isn’t such a good idea either. If not by height, how should you determine a bike size for yourself?

We’re Rodriguez Bicycle Company. In case you don’t know us, we’ve actually been building and fitting custom bikes for 40 years now. 40 years is a long time…longer than most in the bicycle industry. Most of our customers are not professional racers, but ordinary people who want to enjoy a comfortable, high-end bicycle. It only makes sense to innovate with them in mind. For decades, we’ve pioneered bicycle fit, and developed our own complete fitting system (software, fit machine, and fitting tools) to better serve our customers. Most other fitting systems, if not all of them, were designed around professional racing.

I’ve written a lot on bike fit over the years, and I’ll attach some further writing I’ve done at the end of this article.

Why did I write this article?

Every year, I get several customers who ask me “I’m XX tall, which one of your sizes will fit me?” Usually, they’ve already determined that they should ride a certain size based on a height chart from some other bicycle website. I’ve probably already written this article 100 times or more in the form of emails to these customers, so I though it was about time to put it in a form I can reference more easily than trying to dig it out of my head. In fitting a bicycle, there are many more measurements to consider than when sizing for shoes. So what’s height have to with it? Read on and see….

Now Back to our Story:

Important things to consider when determining your new bicycle size:

Your body is a machine with many levers and pivot points, and so is your bike. Our goal is to get them adjusted and functioning as 1 machine. When all levers and pivot points are where they are supposed to be and working together, you will be comfortable and efficient. The length of each lever, and the placement of each pivot point effects all of the others. Inseam is important (and some shops get that right), but how about your femur length? Your femur length in relation to your inseam will determine where the placement of the pivot point (your knee) should be. This relationship will affect greatly the fore/aft placement of your bicycle seat (to get your knee in the right place). In turn, the seat fore/aft position in relation to the handle bars will greatly affect your reach to the handle bars.

Let’s keep rolling

Foot length is also important (there’s that shoe size again) as your foot becomes an extension of your leg when pedaling. Now how about torso length? This is probably the most important measurement, and also the least considered. Your reach to the handle bars is determined by your torso length (as well as other factors mentioned past and post this sentence). Probably 80% of fitting complaints come from improper reach to the handle bars. Arm length plays a strong role as well, and will determine how high or low your handle bars end up in your final fit. Now realize that all of these things play together. Your femur length affects your reach to the bars, so adjusting just for inseam and femur length will throw your bar reach out of whack. Changing your fore/aft seat position will also affect your seat height. It all plays together in determining what frame size will fit you best. If all of this were not enough, throw conditioning, riding style, and injuries into the mix. Now tell me….do you think it’s reasonable to expect a good bicycle fit from someone who considers just your height, or inseam?

Hopefully, I’m making some sense and you’re getting an idea of how it all works together?

Wow! Writing this circular description might make it sound confusing, but it’s really not if you’ve been doing it for as long as we have. Read on and I’ll give a little more down to earth explanation of why all of this is important.

We offer more sizes and custom at lower costs than other companies

It was 40 years of custom bicycle building and fitting that drove us to our 18 Rodriguez sizes. We have multiple sizes for every height of rider, not just one. Our L and S categories take into consideration whether your height is in your legs, or whether it’s in your torso. We fit around 90% of our customers on these 18 sizes, so I don’t know how folks are getting good fits from companies offering just 5 or 6 sizes. How about a custom size? At Rodriguez, it’s just $200 extra if you need a custom. This is because of our new manufacturing philosophy adopted in 2006 (but that’s a whole different story).

If you are getting a size recommendation that considers just your height, how accurate do you think it could be? I, myself, have been fitting bicycles for 30 years, and I couldn’t guess an accurate frame size based only on someone’s height.

OK, so that’s a lot of words, but what if you’re a visual person like me?

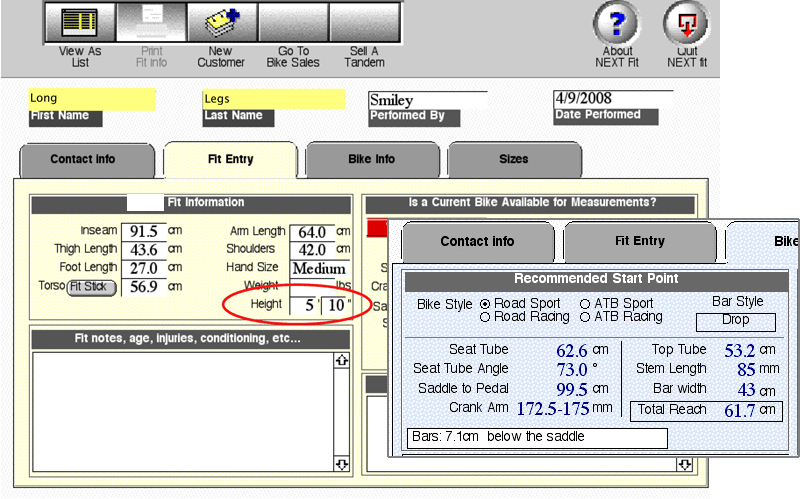

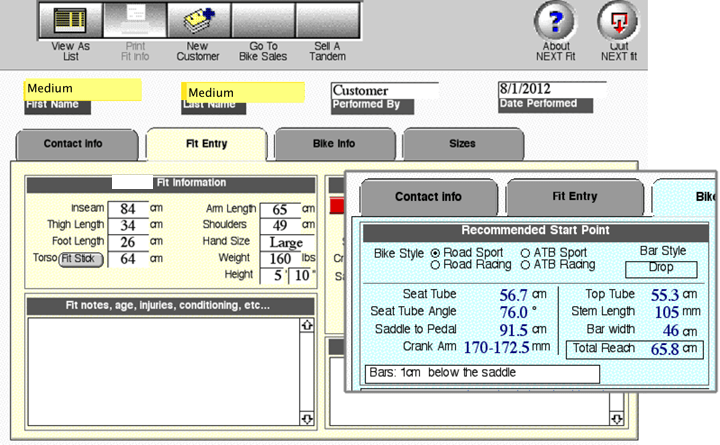

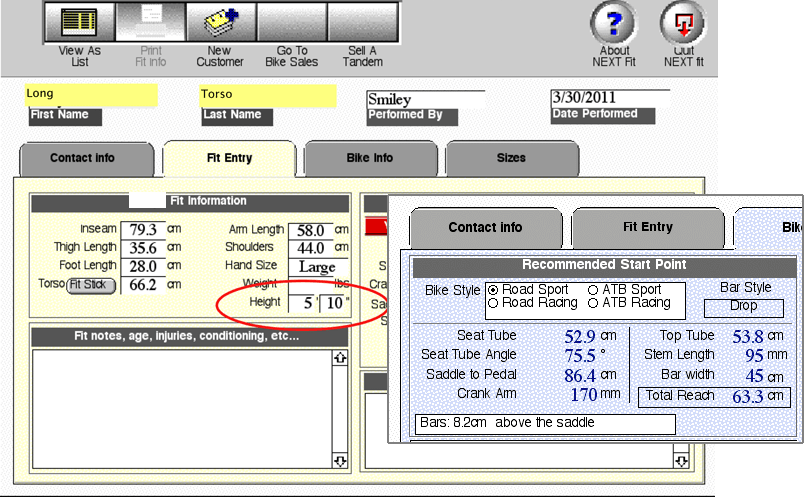

How about a real life illustration of how people of the same height will require vastly different bike sizes? Below are 3 actual fit entries from our NEXT-fit database, with an imposed image of the size recommended from those measurements. Most manufacturers recommend a size based on the Seat Tube length, so that’s the number that their ‘size by height’ chart is pointing you to. All 3 fits represent customers who purchased bicycles from us. All 3 riders are 5′ 10″ tall, and are male. Other than that, there are no similarities in their inseam, torso, arm length, etc…. All of these guys ride completely different frame sizes, and if they traded bikes, they would all give up cycling out of sheer discomfort. Pay particular attention to inseam, torso and arm measurements, and how it affects the seat tube and top tube lengths.

Rider 1 – 5′ 10″ Long Leg customer

Quick synopsis: Rider 1 has the long legs and arms of an ‘assumed’ 6′ 3″ guy, but then a torso measurement more like an ‘assumed’ 5′ 6″ guy. Most companies don’t make a bike for someone of this build. He winds up with a 62cm frame with a short top tube.

Rider 2 – 5′ 10″ Medium Medium customer

Quick synopsis: Rider 2 is a pretty good representation of the ‘averages’ that most companies use to build their sizes, and recommend them by the rider’s height. If you happen to be these proportions (very few people are), then the ‘sizing by height’ method may work out fairly well for you.

Rider 3 – 5′ 10″ Long Torso customer

Quick synopsis: Rider 3 has the very long torso of an ‘assumed’ 6′ 3″ guy, but the arm length and leg length of an ‘assumed’ 5′ 5″ guy. Notice that his short arms put him with an overall reach to bars about the same as the first guy with the really short torso. Although his seat tube length is almost 10cm shorter, they ride the close to same top tube length, but rider 3’s bars are much higher due to the shorter arms.

How do we do it?

‘Long Torso’ and ‘Long Leg’ are kind of extreme examples, but they are indicative of many of the customers we work with every day. If either one of these guys purchased a bicycle online by selecting from a sizing chart determining their frame size by their height, they would both have really poorly fitting bicycles. It’s important to measure your whole body in order to get the right size. Medium-medium guy would probably find that off the rack bicycles may fit him OK as far as ‘sizing by height’, but notice the seat tube angle required for his femur length. Even though his seat tube and top tube would be easy to find in a production bike, he will still end up making a lot of adjustment for his femur length, and then have to adjust for that. If it all seems overwhelming, don’t worry, that’s why we’re here.

At Rodriguez, when we’re fitting a 5′ 10″ customer, we have about 4 sizes that fit about 90% of them (that’s true for just about any height rider as well). The other 10% (of which 2 of these guys are) will wind up paying $200 extra for a truly custom size. A small price to pay for a lifetime of comfort. We work with people online, and in person every day, all day, to get them the most comfortably fitting bike they can possibly have. We have video and written instruction online to help our long-distance customers get their measurements right.

If you’re considering a new bike, and you’d like to work with us online or in person to determine your next frame size, we’d be glad to oblige. We think you’ll find that we’re easy to work with, and we really love our customers….long-distance or local.

Links in this article and related links:

- Our 40 year history of bicycle fitting at Rodriguez

- Rodriguez is a pioneer in the field of bicycle fitting for regular people

- How to get a comfortable bike

- Rodriguez is with you from Fit to Finish

- How we can offer you the Best Value in the Industry

- Rodriguez bicycles are Guaranteed to be Just Your Size

- Our Shop History

- Bicycle sizing Specifically for Women

Weight-a-Minute…..

2013 Update!

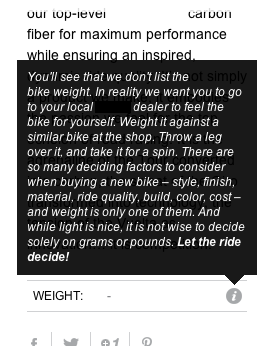

One of the manufacturers that I subtly refer to in this article is no longer publishing weights. I just checked their website, and the disclaimer below pops up when I ‘moused over’ weight.

Kudos for coming clean, and we whole heartedly agree with most of your advice. There are many factors to consider when buying a bike, but we feel the most important factor was left out of your advice. The most important thing to remember is…

Don’t buy a bike buy a whole shop!I don’t read a lot of bicycle magazines, but when I do, I see advertisements for bicycles that weigh 17 and 16 pounds all the time. As you may know, we have a full service repair shop at R+E Cycles, and we repair any brand of bicycle. Quite often a bicycle model will come in for repair that I have seen advertised in a magazine as an ultra-lightweight bike. I’ve been lifting bikes since I could walk, and started to notice the ‘heft’ in some of these supposed ‘ultra-light’ bikes.

Last summer I lifted one that I’d just seen advertised at 17 pounds, and it just didn’t feel that light. I put it on the digital scale that we use to weigh our bicycles, and low and behold, it weighed 21.3 pounds! It was a $5,000 carbon fiber racing bike that weighed considerably more than our $2,800 steel Sport bike. I was perplexed, but soon forgot about it…..until Seattle Bike Expo. Something happened there that just made me say “wait a minute……”.

We built and assembled an S3 steel tandem that ended up weighing 26.8 pounds with pedals and water bottle cages and put it on display at Seattle Bike Expo. In the world of tandems, any verified weight under 35 is considered light. On Saturday, the first day of the show, our bike got a lot of attention. One guy told me that another tandem manufacturer (we’ll call them brand X) had a similar tandem on display that only weighed 24 pounds. Again, I was perplexed because I didn’t see how that was possible, so in the back of my mind I assumed he’d just misunderstood the other salesperson.

An hour or so later, I had another customer who said he had decided to buy one of these 24 pound tandems from brand X. I questioned this customer, and he knew the model, parts, weights, etc… “That was it” I thought, “I’ve got to see this 24 pound tandem!”On Sunday, I stopped off at the shop and picked up our digital scale to keep in my pocket, and then headed down town for the final day of the Expo.

When the show slowed down a little bit, I ventured off to check this thing out. When I arrived at the brand X booth, I said “I heard that you guys have a 24 pound steel tandem over here that I just have to see”.The salesperson, noticing my Rodriguez T-shirt, said, “Well, it’s really more like 26 pounds right now” as he pointed to a very nice looking tandem. Look at that I thought, it’s already gained 2 pounds and it’s not even lunch time. I looked down at the cranks and noticed there were no pedals on the tandem, so I jokingly asked”Wow, there’s no pedals on it? How do you ride it?” “OK so pedals add a pound,and the bike rides at 27 pounds” he answered. I reached out and tried to lift the tandem,but it was strapped down. I said to him “Man, I just have to lift a steel tandem that’s this light, will you undo the straps for me?” As he grudgingly knelt down to undo the straps, I pulled the digital scale from my pocket and said “but I have to lift it…..with this”.

Now, the look on his face kind of told me that this tandem wasn’t going to weigh in at 26 pounds, but even I was shocked at the final weight. As I lifted the bike with the scale the digits started fluttering like a digital scale will, and the Brand X sales person kind of backed away as a couple of onlookers gathered behind me. “Ooohhh”I said, “that doesn’t look like 26 pounds”. “What does it say?” He asked. “32.2 pounds” I answered, as the scale locked in its final weight. “You can’t really build a steel tandem under 30 pounds” came the reply. (I thought this was an odd reply for someone who just told me this bike weighed 26 pounds.) “We’ve got a 27 pounder over in our booth with pedals and bottle cages” I told him. “It weighs 27 on that scale?!” Said both Brand X sales people as they pointed their fingers at my digital scale. “You come on by the booth, and we’ll weigh it together” I said as I headed back to our booth.

Believe it or not, he did come by the booth about an hour later. I whipped out the scale, and we weighed it together like I promised we would. As the scale locked in at 26.8 pounds I jokingly said “I guess I was wrong about the 27 pounds, it only weighs 26.8”. He stood and looked over the tandem for a while and said “that’s amazing”.

It’s all fun and games when a fishermen exaggerates to his buddies the size of the fish he caught, just like nobody gets hurt when someone exaggerates to their friends how light their new bike is. Those exaggerations are called something else when advertised to the public, and this is one local company who’s tired of competing with those ‘exaggerations’ unabated. Be careful you guys when you quote those weights, ’cause I’ve got my digital scale, and I’m not afraid to use it. I like making light weight bikes, and we build some of the lightest bikes around, but I’m never going to recommend that someone sacrifice a comfortable ride, or a good fit in order to make their bike lighter weight. I would also encourage all of these companies not to sacrifice the truth to try and sell a bike, and if they do, I’ll be therewith my digital scale.

If you want light weight, a comfortable high-performance ride, affordable price, and the quality that comes with a hand-crafted bike made right here in Seattle, then I hope that you’ll give us a chance to show you our new S3 frames. Call today to make an appointment to see one, we know you’ll love it.

Thanks for reading

Dan

Originally written June, 2008