Most bike shops slow down in the winter, but we’re as busy as ever with new bikes, new projects, and celebrating with our customers. Here’s a rundown of what we have in the works for 2020:

The Rodriguez Disruptor E-bike and Shift-E system

Our biggest news in the new year is the debut of the Rodriguez Disruptor e-bike with our own Shift-E shifting system. The Disruptor is an e-bike made the Rodriguez way. It’s custom built just for you with a powerful motor and a drivetrain perfect for the high torque e-bike motors produce. The Shift-E drivetrain, exclusive to R+E, can shift under as much as 2 1/2 horsepower. That’s exactly what you need with a 750 watt electric motor in charge. Shift-E also has two shifting modes: manual and automatic. You can control each shift via push button or just put it in automatic and forget it! Shift-E adapts to your preferred cadence for smooth pedaling no matter the terrain.

The Disruptor is how we think e-bikes should be. Light enough to ride like a regular bike, powerful enough for any terrain, and equipped with a shifting system that’s made to withstand the forces of an electric motor. We’re thrilled to see this bike debut to the public and we can’t wait to put you on one.

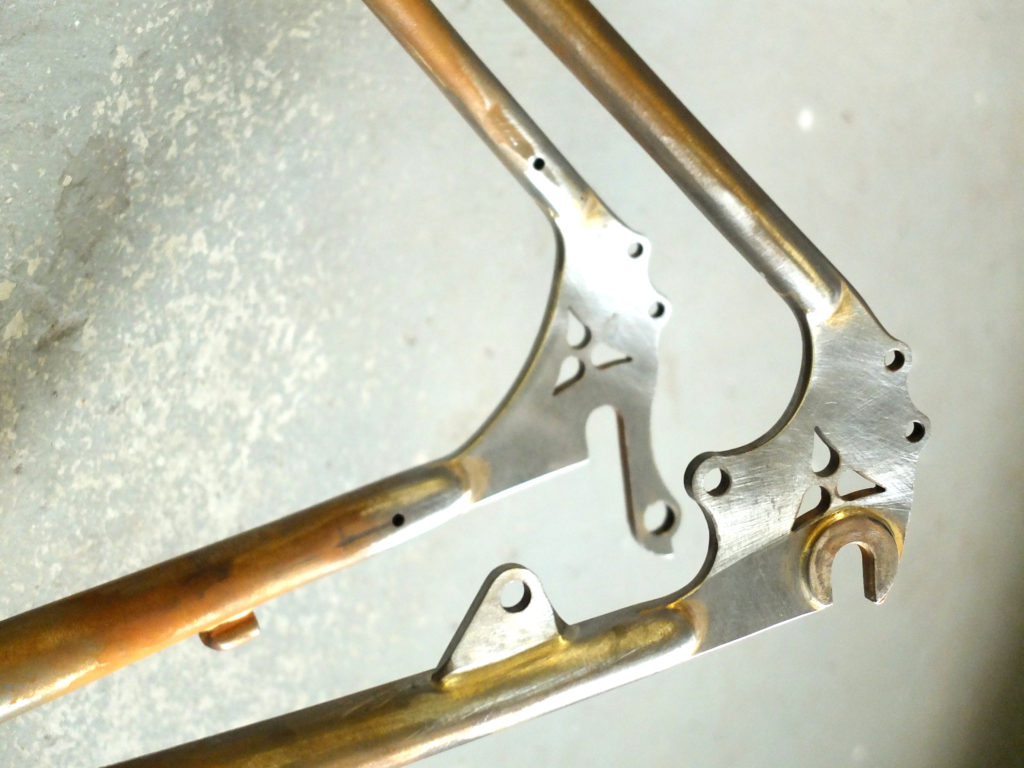

Rodriguez Thru-Axle Dropouts

Thru-axle hubs are one of the biggest changes in bikes this decade. The quick release skewer has been dominant for nearly a century but that supremacy is finally changing. One of the most common questions we get these days is: “Can you do thru-axle?” The answer has always been yes, but we’ve been unsatisfied with the dropouts available from other companies. That prompted us to do what we usually do in that situation: we made our own! These new dropouts fit our building process a lot better than other dropouts and allow us to build a better bike for our customers. You’ll be able to see these on our showroom floor very soon.

Rodriguez Custom Frame Bags

Rodriguez Bikes has partnered with Bedrock Bags of Colorado to produce our own custom frame bags. These waterproof bags are handmade in Colorado specifically for your Rodriguez bike. Since we have your frame measurements, ordering a custom bag is a piece of cake. Whether you’re doing multi-day bikepacking trips, or just commuting in the Seattle weather, these bags are up for the challenge. We’re glad to be offering such a rugged option for our customers in the new year.

Bike and Pike 2020

This year is our 12th annual Bike and Pike open house! Mark your calendars, it’s happening on Saturday February 29th. We’ll have lots of fun stuff on hand, like Disruptor test rides, Pike Brewing beer, corn dogs (probably!), frame shop tours, and tons of good conversation with people that love bikes. It’s a great party every year and this one promises lots of fun new stuff to see and try out. We can’t wait to see you there!

I can assure you this is not a complete list of the interesting things happening at R+E in 2020, but I can say we’re off to a great start. Keep an eye out here and on our social media to see what we may be plotting in the new year.