At Rodriguez Bicycle Company, we build a lot of tandems. We’ve done it for 46 years now, and in that time we’ve learned a lot. Tandems require a different approach than single bikes. Every force put into a single bike during a ride is at least doubled, and sometimes tripled, when riding a tandem. This means every design decision has serious repercussions for ride quality as well as rider safety. In this article we are going to explain why and how we make these decisions when building a Rodriguez or Erickson tandem. We’ll take them in order of importance.

Fit – the most important decision

Every Rodriguez and Erickson tandem is built custom to the riders’ exact fit. Every one. This sets us apart from every other tandem manufacturer. We’ve learned that a tandem that isn’t comfortable to ride is a tandem that sits in the garage, unridden and unloved. Fitting one rider to one bike can be challenging, but fitting two riders to one bike requires the extra effort of a custom frame. This also allows us to build each tandem to perfectly suit the goals of each team of riders, whether that’s a 26 pound ultralight race tandem, or a double step-through tandem frame for an older (uh…wiser) couple that just wants to keep riding together as long as possible. We meet you where you need to be.

Fit is also the reason we rarely use a belt drive for our timing gears. We get a lot of questions about Gates timing belts for tandems these days. They work well to connect the two cranks together, but they are restrictive in one particular way: they drastically limit how long the stoker cockpit can be. A comfortable stoker is a happy stoker and forcing them into a cramped, short compartment is never a good idea. Although the timing belt looks cool, it will look less cool sitting in the garage because your stoker doesn’t enjoy riding the tandem.

We do build occasional tandems with belts if the stoker’s fit works out. If belts become available in variable lengths, and we can build without stoker comfort compromises, we will be happy to recommend them to more couples. Until then, consider what problem you’re trying to solve with a belt, if any, and whether the compromise is worth it.

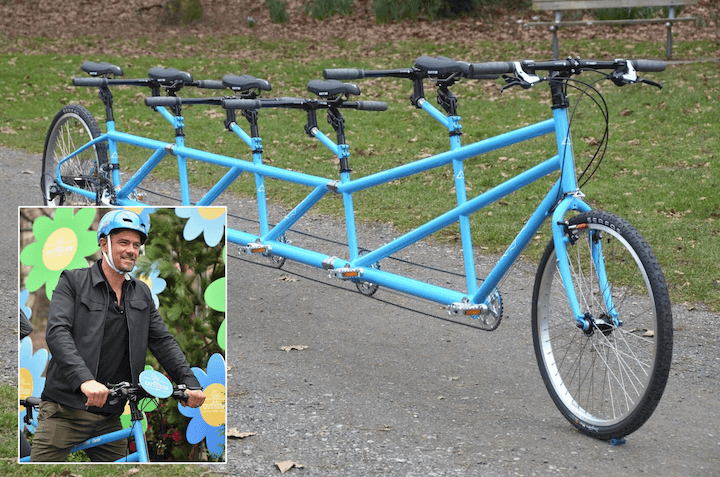

The tandem above uses a belt for timing. As you can see the stoker’s handlebars end up almost directly under the captain’s saddle. The Rodriguez tandem on the bottom has a much roomier stoker cockpit, allowing for greater comfort and fit flexibility. Note the lack of stiffener tube in the top tandem as well.

Frame – the most permanent decision

To the untrained eye, tandem frame designs can look very similar, but to an experienced builder there are subtle yet important differences between designs. Our design choices can add complexity and time to the frame building process, but we think it’s worth it to our customers.

Designing a tandem frame is a formula that balances strength, handling, and rider comfort. The frame needs to be stiff enough to handle two riders putting all their weight and strength into it while still being compliant enough to give a smooth and comfortable ride. If a tandem is too stiff then it will be jarring to ride and therefore unridden. This is why we almost always start with steel. It provides a reliably smooth ride, fantastic strength, and can be made as light as the riders require for their needs. Desired riding characteristics can be achieved through tubing choices, tube shape, and geometry design all of which are fine tuned to the owner’s needs. These decisions build the foundation on which all the other parts rest.

One feature that almost all of our tandems have is a stiffener tube that transverses the length of the bike from the head tube to the stoker’s bottom bracket shell. (see the above image) Correctly mitering a tube to join the bottom bracket correctly is a difficult process, but one that we know is worth it. It stiffens the frame overall, but by joining the tube directly to the bottom bracket you gain a frame resistant to the twisting forces of the stoker’s pedaling and a frame much less likely to crack from stress. Our stiffener tubes are also one continuous tube, not two tubes welded into place. (see image below) Again, this is more difficult, but worth it for the strength and stiffness this method provides. A pierced tube will not flex at the captain’s seat tube the way a pieced together tube will.

Here’s an example of a junction assembled with pierced tubes. Piercing, rather than joining two separate tubes, maintains maximum strength and rigidity.

Most tandem builders have stopped using stiffener tubes in recent years. This is to save time in their build process. Time is money, after all. Some believe it makes the frame lighter, but is that true? Surprisingly, no. All the other tubes have to made stronger and heavier in this type of design so any weight savings is negated. Leaving out the stiffener tube also results in a frame this is less resistant to flexing at the stoker’s bottom bracket. The frame will be more likely to twist under load even if the other tubes are heavier because there is no triangulation. While we do offer lower priced Rodriguez tandems without stiffeners, they are not the main choice of our customers who want a high performance build. Leaving out the stiffener saves the builder money, but there is no getting around the fact that it is a performance compromise.

Fork – critical to both handling and safety

There’s no getting around how critical the fork is to tandem riders. It needs to be stiff and it needs to be strong. We have two styles of tandem forks and both are made from steel. Unlike a single bike, where we can use aluminum or carbon fiber forks, tandems work better with traditional steel forks. We have a heavy duty fork that can handle the weight of the riders as well as a fully loaded touring setup with panniers and frame bags. We also build a lightweight steel fork for riders that want to save weight but still have a fork that they can rely on in difficult situations like sprinting and cornering under speed. Having a fork that flexes too easily, especially in regards to the steering tube, can ruin the handling of an otherwise well built tandem.

For these reasons we no longer use or recommend carbon forks in our tandems. While many carbon forks perform well on single bikes, they have proven to perform poorly on tandems. Carbon steering tubes flex more easily and are more prone to breakage than a steel steering tube. The legs of a carbon fork have the same issue and can provide a “noodly” effect even if they are built strong enough to stay intact. There are also few carbon fork manufacturers that will warranty or recommend their forks for tandem use. They know it’s not a good idea. Even so, many tandem manufacturers put these carbon forks on their tandems even though the fork maker has specifically stated ‘not for tandem use’. If the fork manufacturer says it’s not strong enough for a tandem, you should believe them.

Safety aside, the benefits of a steel fork in both handling and reliability for tandem use greatly outweigh saving a couple of ounces of static weight.

Components – fine tuning your needs

Tandem components go through a lot. Shifting gears can be especially challenging with two people applying force to the drivetrain. Stopping a tandem requires more than 3 times as much force as a single bike, thanks to the Inverse Square Law. Wheels on a tandem need to be especially strong to hold up to the forces of cornering, climbing, and descending under two adult riders and the things they carry with them. We can carefully curate a set of components for your tandem that will meet your needs and hold up for the long haul. These choices will be part of the conversation when you get a tandem from R+E. One size does not fit all and we keep this in mind when building your tandem.

Experience – the last crucial piece

All of this information and insight comes from building and riding tandems for decades. Every part of our design has been looked and revised over the years and we are confident that we are building the best tandems in the business. We build because we ride, and we don’t want to build something we wouldn’t want to ride ourselves. If you want to know more just give us a call or shoot us an email. We will be happy to have a conversation and go into as much detail as you need.

For more information on our history with tandems, check out the articles below:

Other articles on bicycles, tandems, and the bike industry can be found here.