This post is part of an ongoing series profiling Rodriguez bikes that have been taken the extra mile by the customer. Today’s is a Rodriguez Rainier travel bike with impeccable aesthetics.

This customer had a clear aesthetic vision when they pulled the trigger on building this bike. Designed as a light touring road bike, it hits all the visual notes of a classic bike. Built with a few modern upgrades, it’s a beautiful expression of vintage bike style. As we go through the details, you can see where some compromises were made, but the overall look stayed true.

Let’s start with the drivetrain. The MicroShift derialleurs were an easy choice. They come in silver and work dependably with Shimano shifters to shift triple chainring reliably. This is also why the bike is 9 speed instead of 11. (see our post about drivetrains if you want to know more about gearing configurations) Silver parts go in and out of fashion in the bike industry and can be easy to find one year, hard the next. We’re glad companies like MicroShift help keep silver parts available for bikes like this.

These DaVinci crank arms really round out this drivetrain configuration. When our customers want a triple crankset that’s both light and pleasing to the eye, DaVinci is our go to option. The square taper design and modular spider allow us to fine tune both Q-factor and ring spacing so that we can get everything just right for the customer and their needs.

At the heart of this bike, and influencing it’s look, are the stainless steel frame couplers from S&S Machine. Not only are they essential to the travel aspect of the bike, they’re a component that meshes well visually with a classic style bike. The honey leather Brooks saddle atop a Velo Orange extra-setback seatpost are a look unto themselves. The post is essential for most riders that want a Brooks but also want a standard seat tube angle. This post gets the Brooks in exactly the right spot for most people. Velo Orange also supplied the retro style woven metallic cable housing used on the bike.

The brakes are silver Tektro R539 long reach calipers, which is our stock brake for the Rainier. Using stainless steel Sheldon Nuts to attach them gave us perfect mounting points for the Velo Orange smooth aluminum fenders. Velo Orange leather mudflaps accent the more prominent leather components of the bike while keeping the rider’s feet and friends dry.

The owner chose to put a significant portion of their budget into a very lightweight set of wheels. High polish White Industries T11 road hubs laced to Stan’s Alpha 400 rims with DT Swiss butted spokes and 7075 alloy nipples. The lacing pattern is also weight saving, with a radial laced front wheel and a rear with a radial non-drive side and a two-cross drive side. The rigidity of the Stan’s rims made building with these lacing patterns a no-brainer and allowed us to build a wheelset just over 1400 grams. That weight savings made it worth the aesthetically incongruous use of a black rim instead of polished silver.

There’s also a nice weight savings with our Rainier carbon fork. While not ultra-light, our fork offers a lighter option to a steel fork with the resilience of an aluminum steer tube. Fastened with a set of the Velo Orange skewers that resemble the old Campagnolo skewers, it’s a visual package that works well.

The handlebar setup really helps tie together the whole bike. The black Shimano Sora shifters, honey leather Brooks tape, and silver Soma HWY One bars work as color touchpoints to the rest of the bike. The Crane E-Ne brass bell is a lovely flash of gold on an otherwise silver outfitted bike. These shifters were chosen for their ability to shift a triple, but ended up working visually with the bike. They match nicely with the black rims that would otherwise look out of place.

This bike is a great lesson of how to get what you want while spending your budget where it matters the most. Helping our customers maximize their budget while still getting the bike they want is one of the skills we’re happiest to share. For the curious, here’s a complete parts list:

- shift/brake levers – Shimano Sora 3×9

- derailleurs – MicroShift triple

- brakes – Tektro R539 dual-pivot caliper

- crankset – DaVinci aluminum triple

- chainrings – Shimano 50/39/28 triple

- bottom bracket – Shimano UN-54 square taper

- cog set – Shimano 11-32 9 speed

- chain – KMC 9 speed

- hubs – White Industries T11 road

- rims – Stan’s No Tubes Alpha 400 700c

- spokes – DT Swiss Competition 14/15g double butted stainless

- nipples – DT Swiss 7075 alloy

- tires – Panaracer Pasela PT kevlar bead

- skewers – Velo Orange QR

- headset – FSA Orbit X 1-1/8″

- stem – Dimension alloy silver

- handlebars – Soma HWY One shallow drop alloy silver

- bar tape – Brooks leather

- seatpost – Velo Orange extra setback silver

- seat collar – Dimension silver

- saddle – Brooks Swift leather

- fork – Rodriguez Rainier long reach carbon – custom painted

- fenders – Velo Orange smooth aluminum

- couplers – S&S Machine stainless

- cables and housing – Velo Orange metallic braid

- cable splitters – DaVinci

- bell – Crane E-Ne brass

- mud flaps – Velo Orange leather

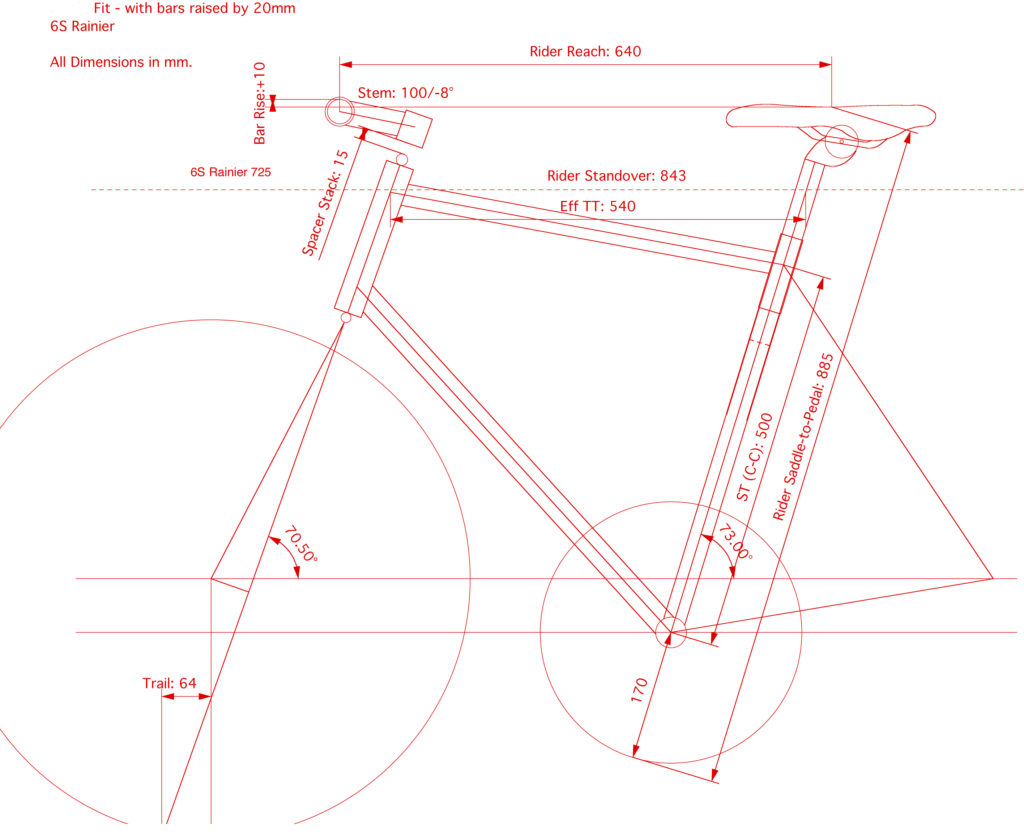

For the really curious, here’s the fit drawing:

We’d also like to thank Sockeye Cycle in Haines, Alaska for connecting us with this customer. If you’re looking to ride Alaska, they’re a great place to start.