One of the most visited pages on our website over the last year is our Xtra-long bike page. There’s not many manufacturers that make bicycles for 3 or more people, and for some reason, there’s a lot of families interested in them right now.

Even with all of that interest, some people have a hard time committing to owning one of these creations. There are a few obstacles that can make these bikes impractical to own. These were all things that I struggled with too before I designed the Xtra-long bike that my family rode for 6 fun years. I thought I should share my experiences and let you all know why we make our Xtra-long bikes the way we do. There are some Rodriguez differences that can save you thousands of dollars. If done right, your experience can be amazing, and can create great bicycle memories for you and your family to look back on. I know this personally.

So, let’s get down to business. Here’s the objections most people have to actually jumping in and buying one of these bikes.

1.) How do I store it?

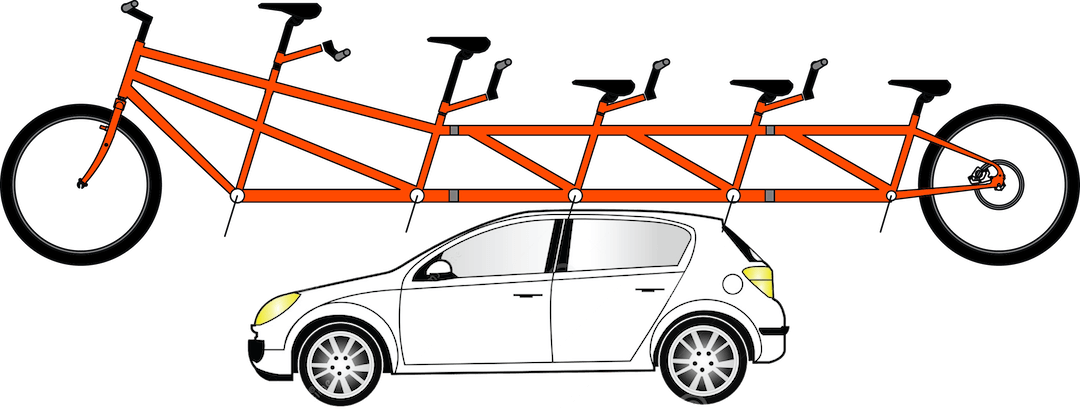

A bicycle built for 3 is too long to hang on a ceiling hook. One built for 4 or 5 can be up to 15 feet long. Where’s that going to go?

2.) How do I transport it?

There are lots of ways to transport a single, or even a tandem. But a triple, quad, or quint is so long that it won’t fit on top of a car or in the back of a pickup truck.

3.) It’s such a specialty bike. Will it get ridden enough to make it worth the price?

Most people who want a triple, quad or quint already own single bikes and a tandem. So, adding another expensive bike that will only be ridden if all parties are available seems impractical.

You can benefit from our experience

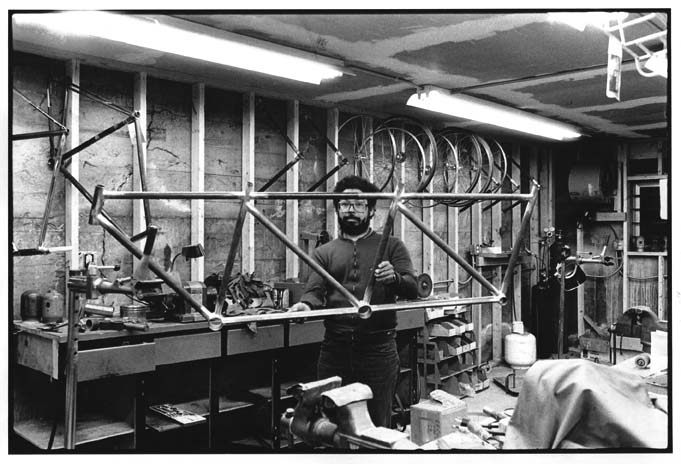

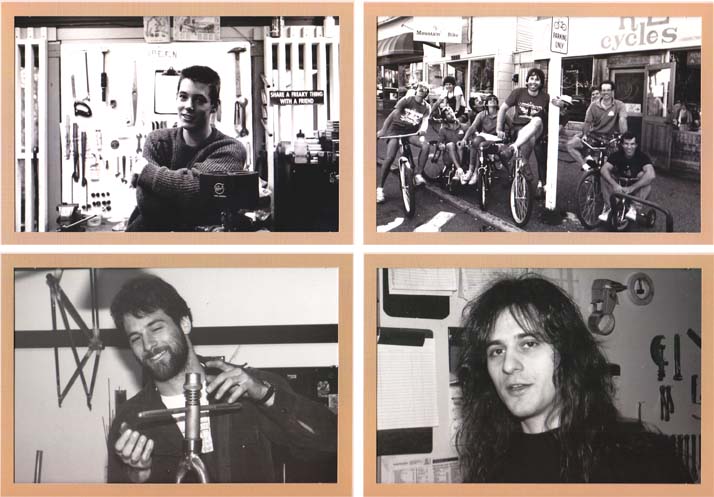

After years of building bicycles for 2, 3, 4 and 5, we’ve learned a thing or two. We are one of the oldest, if not the oldest, of the Xtra-long bicycle manufacturers still building in the U.S.

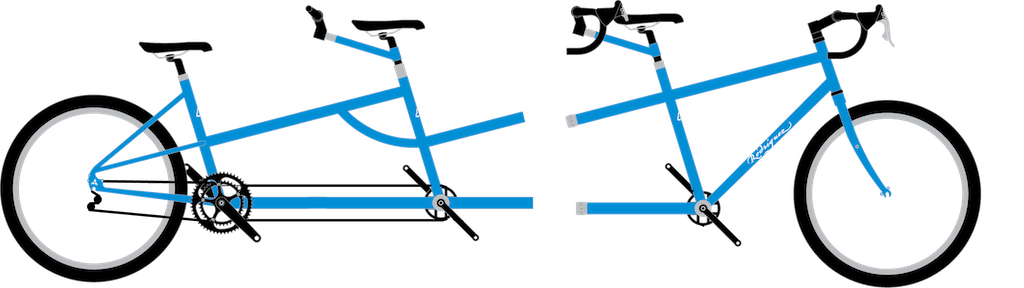

My family rode a bicycle built for 4 for several years while my kids were young, so I have a lot of experience in the subject. These are all things that I struggled with before we built our quad. The solution: S&S couplers and some Rodriguez ingenuity.

Let me tackle these obstacles one at a time.

1.) Storage: This one is very easy to solve. Every Xtra-long Rodriguez includes at least enough S&S couplers to take the bike into 2 parts quickly and easily. Having two halves makes storage much easier (take it from someone who knows). There is no extra charge on our Xtra-long bikes to have this feature.

2.) Transporting the bike: Another huge benefit for the S&S couplers in your new Rodriguez Xtra-long bike is transporting it. In my case, I simply took the bike in half (takes about 2 minutes), and was able to easily fit it in my little clam-shell style tandem hauler. I could fit the whole quad in there, as well as my road bike, the kids bikes, and all of our luggage for any trip we took. If I didn’t want to use the trailer, I could easily haul the bike as a tandem on my tandem rack, and the other 2 sections were small enough to put in the back of the van behind the rear seat.

Having enough couplers to take the bike into 2 parts is a must for all of our Xtra-long bike customers, and that’s why we include at least enough couplers for that to happen at no charge.

3.) It’s such a specialty bike, will it get ridden enough?

This is certainly an important consideration for most families, and was for us as well. Truth be told, if I would’ve just built a quad for our family, I don’t think it would have been ridden enough to make it worth it. Sure, we could’ve saved a little money up front, but it would be really expensive in the end. Read on…

S&S couplers, strategically placed, can make your Xtra-long bike quite manageable

This is where Rodriguez ingenuity really comes in. I designed our bike to be easily convertible from 2, to 3, to 4 in just minutes. Here at Rodriguez, we have a staff of rare birds, so anything is possible. The frame shop team can build just about anything, so this was no challenge at all to build.

This turned out to be the best money spent. As it turned out, most of the riding we did on this bike was done as a tandem. Even on vacation, I left the bike set up as a tandem and we did morning rides as a couple. Then, if the weather was good, and the kids wanted to ride, I made it into a quad. We could do a leisurely family ride into town and have ice cream. If one kid preferred to stay at Grandma’s house instead of riding, we left that section out of the bike. It was like owning a tandem, a triple and a quad, but a lot less hassle (and expense).

The Wrap-up and Recommendations

Make sure your Xtra-long bike is a vacation bike Instead, it went on every vacation we took from 2006 ~ 2013, and was ridden in some configuration just about every day on those vacations.

Riding into Rupert, Idaho for the 4th of July parade on a quad was a blast for us and the kids. Believe me, cars slow down when they see a quad, and they usually roll the windows and start asking questions (which the kids love to answer). Riding through the Idaho farmlands as a family ‘racing’ Grandma and Grandpa on their tandem made for some lifelong memories. Then, while Grandma and Grandpa kept the kids for a few days, Marcie and I could take the tandem and spend the time in Sun Valley riding the trails up there.

At home, we left the bike as a tandem for our morning rides. It was our only tandem. We didn’t need multiple bikes. On weekends through the summer, I often put it back into quad mode and we went for an evening ride. Again, ice cream, dinner, coffee shop, you name it. Riding with the kids is quite a bit different than the 2 of us riding as a couple.

Had I built it as a quad only, this would’ve been the only riding it ever got. Instead, it got ridden several times per week as a tandem, occasionally as a quad around town, and almost every day of our vacations. Like we say, a bicycle that gets ridden is a happy bicycle.

Would we do it again? Back on Point Thanks for reading, and I hope this clears up some of those nagging questions so you can go ahead and order your Rodriguez Xtra-long bike 😉 Thanks for reading – Dan – 2017

Had we just built it as a quad only, then I don’t think I would’ve bothered taking it on vacation with us. The tandem is a must, as are the single bikes. So, how would I take all of those bikes, as well as the quad? Answer: I wouldn’t have. That would’ve been a shame, because it turned out that the most fun we had with this bike was on vacations.

Riding into Rupert for the annual 4th of July parade in 2007. Photo Courtesy of Grandma Sally

Yes, absolutely! Our kids have outgrown the quad, and it was sold in 2014 for someone else to enjoy. But the memories live on. The only thing I would’ve done differently is that I wish we would’ve done it 3 years earlier. Having 3 more years to enjoy the family quad rides would be something we would cherish. That being said, I really loved the 6 years we had on the bike, and if it’s in your budget, I highly recommend it.

Obstacles to owning an Xtra-long bike: As you can see, all of these obstacles can easily be overcome here at Rodriguez. It might cost a little more up front, but it certainly saves a lot of money to have one bike that can serve as your everyday tandem, your vacation bike, as well as your Xtra-long family bike. Not to mention the added bonus of strorage and transportation.

Our patent has been issued!

Our patent has been issued!