One purpose of this blog is to take a fair look at how current trends are shaping the bike industry and bike design. How we see things is greatly influenced by our long experience as bike builders, and here we try to be as fair as we can.

Today, we’re going to take a look at the Thru Axle vs Quick Release debate that has been steadily providing snarky comments online for at least the past few years. First, a little history.

The quick release skewer and axle system was patented in 1930 by Tullio Campagnolo. He came up with the idea when a misbehaving wingnut cost him precious time during a race. Using a combination of a hollow axle and a skewer with a cam lever on one end and a nut on the other, racers became able to change their wheels in seconds. It went on to become the standard wheel attachment system for road bicycles, and the overwhelming majority of bicycles come with quick release skewers to this very day.

One thing Tullio never got to see in his lifetime was a modern full suspension mountain bike with disc brakes. The combination of suspension forks, disc brakes, and the ever more punishing demands of downhill mountain bikers proved to be too much for the quick release system as it was designed. The legs of a suspension fork really like to move independently of one another, which led to broken axles, dislodged wheels, rotor misalignment, and poor tracking of the front wheel during turns. This changed about ten years ago with the invention of the thru axle system. It linked the two ends of the fork in a new way which stiffened the front end, improved handling, and prevented mechanical problems experienced with quick release systems. Sounds like a win in my book.

So what makes this controversial? This is where the disc brake equipped road bike enters the picture. (The use of disc brakes on road bikes is it’s own controversy that we will not get to today, thankfully.) Disc brakes work great for mountain bikes, so lots of people decided they’d be great for road bikes as well. The disc road bike has proliferated and is now one of the hottest selling types of bike in North America and Europe. Along with this change came a call to also bring the thru axle over from the mountain bike world. This brings us to the question we have today: was this an improvement for road bikes?

Road bikes use a rigid fork that doesn’t experience the same issues as a suspension fork on a mountain bike. It does, however, have similar forces to deal with in relation to the disc brake itself. When a disc brake is applied to a moving bike, the fork blade it’s attached to experiences a large amount of torsional force, which basically means it wants to twist and flex in ways that rim brakes don’t cause. The fork blade has to be beefed up to accommodate these forces or it can fail during hard braking. The thru axle is supposed to stiffen the entire fork and mitigate some of these forces. Benefits are said to include better brake rotor alignment, better handling, and less flex-related rotor rub. The reality is that while these things are true, the amount of improvement is marginal and the majority of riders wouldn’t notice the difference. That’s not to dismiss thru axle, but to say that while game changing for mountain bikes, thru axle is a minor change for road bikes.

I also wouldn’t write off the quick release just yet. It still has the advantage of being a lighter weight system overall. It’s easy to use, easy to replace parts, and you can find compatible parts all over the world. Disc brakes and thru axles carry a weight penalty that’s easily avoided with a traditional rim brake road bike with quick release wheels. Weight seems like less of a concern for new bikes than it did just five years ago, but I doubt that applies to everyone. The good news is you still have the choice, no matter how you choose to roll.

You may have noticed I haven’t said anything about the rear axle. That’s because it makes even less difference than in the fork. Results seem to be about even as far as performance in road bikes goes.

So what should you do as a consumer? As far as I can tell you’re good either way so don’t be overly concerned about it. If you’re thinking about a getting a bike, either quick release or thru axle will work fine. I do believe that most of us will end up with a thru axle bike eventually. I think it’s here to stay at this point, but you’ll still have a choice for some time to come. If you’re the type to get the newest version of things you probably already have thru axle and love it.

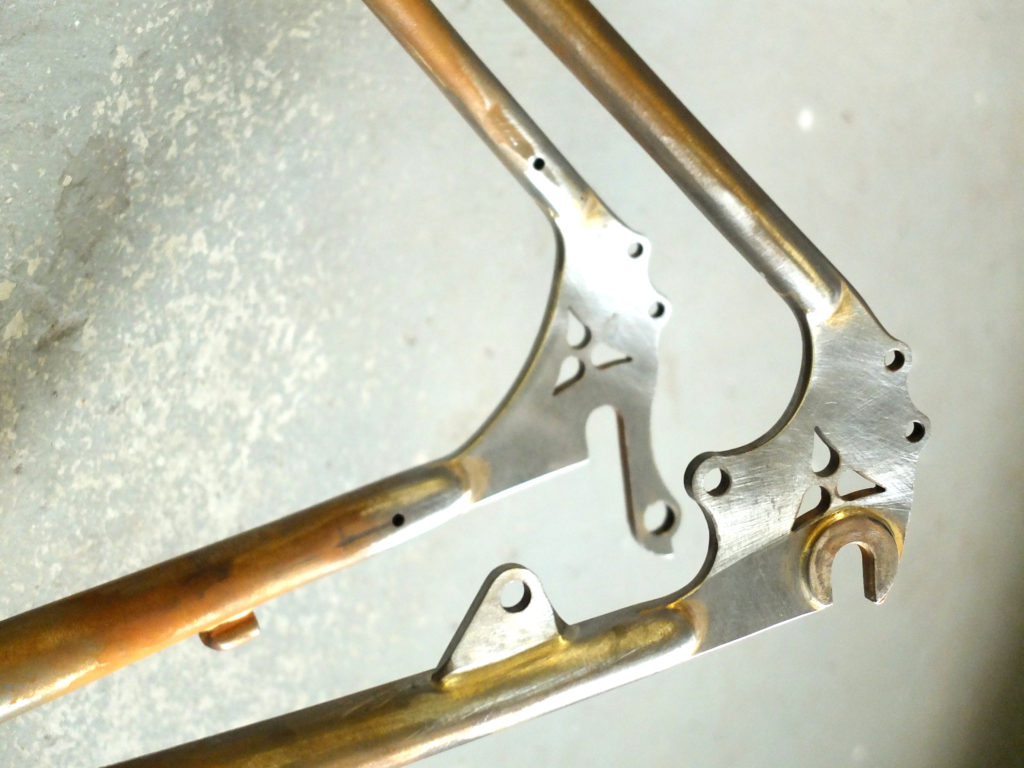

I can tell you what that means to Rodriguez bikes. As a builder that specializes in steel, thru axle represents some new challenges. The fork is actually the easy part. There’s a larger variety of forks on the market than ever before and we’re happy to use whichever one is best going to suit your needs when we build your custom bike. The rear triangle is more of a challenge. We’re happy to build a frame with thru axle dropouts, but it does take more time than traditional dropouts. Alignment needs to be maintained throughout the build and there’s less margin for adjustment. When building a frame, time definitely equals money, so thru axle frames will be more expensive. They will also be heavier, even with the lightest thru axle dropouts we can find. We wish that wasn’t the case. Our favorite thing is giving our customers exactly what they want and we wish all of these options were equal in both weight, time, and cost. That said, we’re a custom shop. We always find a way.

To learn more about our methods go to our website

Here’s another article about flat mount and post mount disc brakes

This is another blog post about whether or not tubeless tires are right for you