This article is from 2012. To read an updated version, Click Here.

The 1970’s

Earth shoes, Flower Power, and lots of hair!

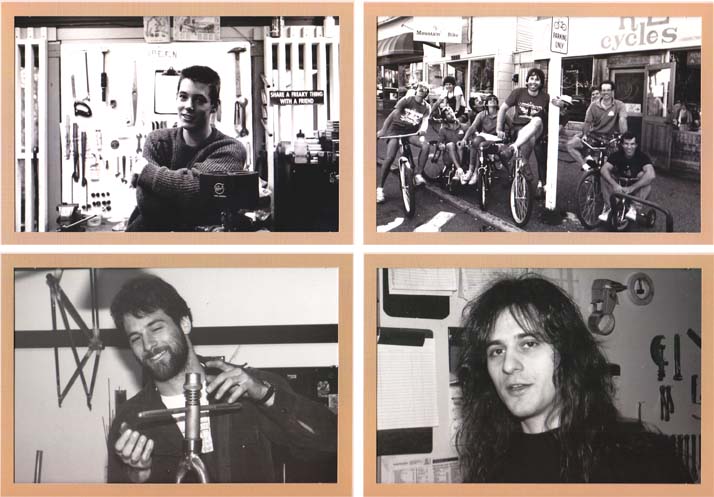

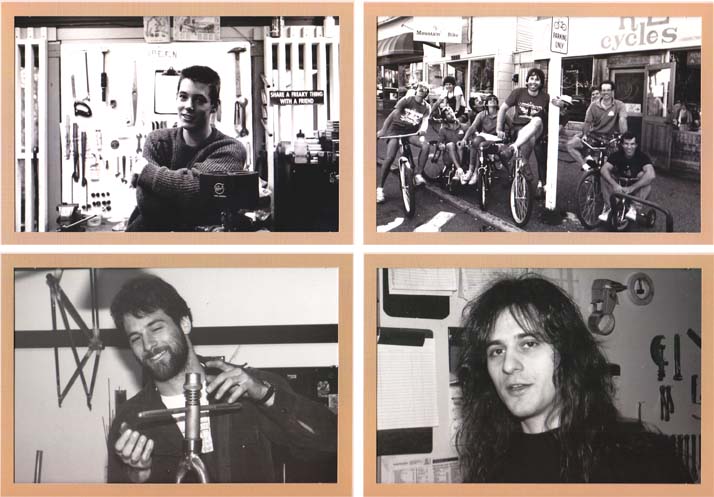

Rodriguez bicycles was established in 1973 by Angel Rodriguez (2nd from left in photo) and Glenn Erickson (left most kneeling person in photo). The sales and service shop was (and still is) called R+E Cycles. A lot of people assume that R+E Cycles is a regular bike shop, and just happens to sell Rodriguez and Erickson bicycles. Actually, R+E Cycles is Rodriguez and Erickson cycles, and is the only place to buy them as well as the manufacturer. The photo to the left shows what the staff looked like in the late 1970’s as the shop began to grow. Angel and Glenn began building bicycles and tandems under their own names, sponsored a racing team, and soon had one of the most respected shops in the city of Seattle.

It didn’t take Angel and Glenn long to attract the attention of business publications in the bicycle industry. Here’s an article from a 1976 issue of Bicycle Dealer Showcase magazine.

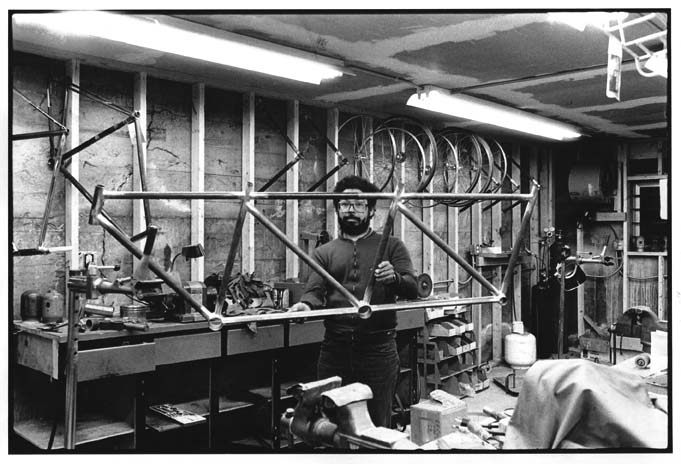

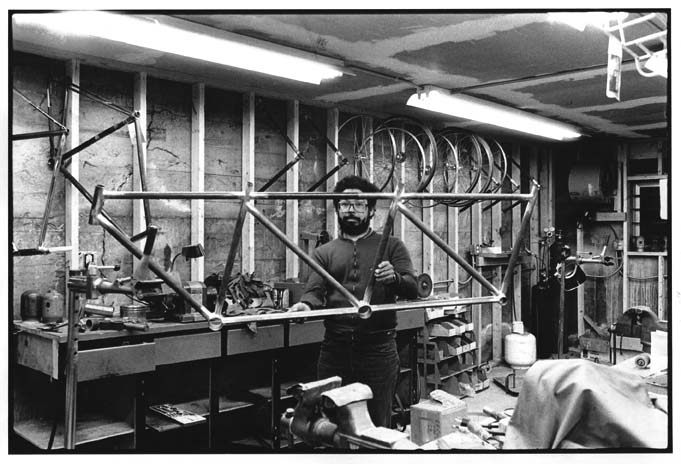

To the right, Angel Rodriguez shows off a Rodriguez ‘bicycle built for three’ frame in progress.

circa 1979

Some photos taken for the

Some photos taken for the

1989 Rodriguez Tandem Catalog

The 1980’s

Max Headroom, Hair Metal, and Madonna are all the rage!

After Angel and Glenn part ways in the early 1980’s, Angel expanded the shop throughout the decade. He worked with the city of Seattle to secure Seattle’s first ‘on-street’ bicycle only parking area. It would be would be 30 years before it’s time!

In the 1980’s Rodriguez bicycles put together a professional tandem catalog, and soon Rodriguez tandems are being shipped all over the United States. Angel also opened the first ‘all mountain bike’ store in the Northwest, Mountain Bike Specialists.

This is the decade when I (Dan, the long haired guy in bottom right photo) first came to Rodriguez Bicycles. I (Dan) started in 1987 as a bicycle fitter and salesperson, and soon was managing the repair and assembly departments until 1991.

In the 1980’s Angel Rodriguez also started a new name brand of bicycles, TerraTech, and had them produced in Japan. These were produced in a touring model and a couple mountain bike models. The TerraTech became a favorite with bicycle commuters all over the Northwest. We still see dozens of TerraTechs each year in the repair shop getting overhauls or updates.

By the end of the decade, this expansion culminated in the shop being voted the best bicycle shop in the country by the readers of Bicycle Magazine. Now R+E Cycles had over 50 employees and had become one of the most reputable shops in the United States. The mountain bike craze helped propel cycling in general to new heights, and Angel Rodriguez had ridden the wave to the top of the industry!

Darker clouds were on the horizon though.

The 1990’s

Grunge Metal, corporate downsizing, and the tech bubble dominate the Seattle news through the 1990’s!

Angel sold the company in 1990. The new owner was not from the bicycle industry, and took the company in a sharply different direction. After losing confidence in that new direction, I left in December 1991. My departure was followed by a few more key employees.

The 1990’s were a brutal decade for big bike shops like R+E Cycles as well as the industry as a whole. Several of the shops voted in the ‘top ten’ of the Bicycle Magazine readers poll of 1990 were out of business before the end of the decade. By 1993, R+E Cycles would almost meet the same fate. In May, 1993 the new owner of R+E Cycles filed for bankruptcy and the doors were shut. The Seattle Times reported on the Cycling Institution ‘Out of Business’ after 20 years. Just a week later, the same paper would be running a different story though. One about a Second Chance for the shop at the hands of Angel Rodriguez with a few others in the background.

Since Angel had financed the sale of the business, he ended up getting the business back. As it turned out, it was just a shell of what it had once been and the inventory had been decimated. Angel Rodriguez called me at home one night. He asked if my wife and I, along with Estelle Gray (one of the key employees that left when I did) would be interested in purchasing what was left of R+E Cycles from him. I answered an immediate “yes!” and because my wife was working in China for 3 months at the time, she couldn’t talk me out of it. I quit my job and joined Angel the next day working to put the shop back together. Estelle joined us as soon as her two-weeks notice was up at her job, and my wife, Marcie, joined us after her return from China.

The Come Back 1993 ~ 1999

I could write a book about those first 5 years, but I’ll spare you that at this point. Suffice it to say that we worked extremely hard to bring R+E Cycles back to life. They were the hardest 5 years of my life, and I had no idea that humans could actually endure the amount of fatigue that we went through in the 1990’s. To the right are a few pictures of the worn-out team (Johnathon, Robb, Myself, Marcie, Estelle and Cindy) taking a rest from construction. We worked night and day to construct an entire, new retail floor.

I put together some of the photos of the re-birth of R+E Cycles if you dare to look. Realize that we were on a shoestring budget, everything was on the line, and we had to work tirelessly to achieve success on this project. We often slept at the shop during that first year as we just kind of passed out on the floor. The friends that you see in the photographs helping us are just some of the people that we owe so much gratitude to. This is the first time I’ve taken these photos out, and I realize that we had some amazing friends helping to make it through that first year. Thanks everyone.

By 1995, we had a

web site up and running (in those days bicycle companies did not have web sites). The internet was very new, but the site did generate some interest from long distance customers, and we sold a few bikes through the site. It’s hard to believe now that a company could survive very long without a web site, but back in 1995 it was still a novel concept. We also began the process of computerizing more than just our bike fit, but our whole process. It doesn’t sound like much, but in the 1990’s computer programming and running a bike shop were not done together. We were technically advanced enough that by 1998 we even attracted the attention of a local computer magazine who ran a feature article on us.

In addition to rescuing the company, we managed to design and build an industry favorite women’s specific bicycle line through the 1990’s. In 1996, the Rodriguez Stellar was born. A U.S. made bicycle that sold for less than $1,000! Nobody had anything like it, and we sold thousands of them. In 1997, the Stellar managed to attract the attention of Bicycling magazine for a review. We also made headway back into the tandem world with the sub-$2,000 Rodriguez Toucan tandem. Before the end of the 1990’s, we had a full line of U.S. made production Rodriguez bicycles to add to our custom line-up….just in time for the dot-com bubble burst.

Not too shabby I say, for a company that was down for the count just 6 years earlier!

2000 ~ 2010 A new Millennium!

Y2K panic, America is attacked, but Lance Armstrong kicks butt anyway!

The year 2000 was preceded by a period of medai hype fueled fear of some sort of world wide computer collapse of mythic proportions. Well, that didn’t happen, but what came next was worse. After the World Trade Centers were brought down by terrorists on September 11, 2001, sales in our store came to an abrupt halt. Soon, the country went into a recession. Fear of flying was causing cancellations for Boeing airplanes. Boeing is a huge part of the economy out here in Seattle, so airplane cancellations turned into bicycle cancellations.

2008 Staff Photo

By 2003, R+E Cycles needed to go through yet another transformation. The shop had shrunk from 22 employes down to 6, and my business partner retired and moved away. We needed to reach out to a national audience if we were going to grow the company again. We did this through expanding and improving our website, redesigning our entire line of bicycles, and re-tooling to make our prices more competitive. We’re a ‘do-it-yourself’ kind of company, but we managed to put together a website that attracted a much larger audience from outside Washington. Soon we were hiring again and building bicycles to ship all around the country and even the world. By late 2003, our focus on service even attracted the attention of The Seattle Times who called me for a quote when a new bicycle Superstore was opening down the street from us.

We also put in a coffee shop (Pedal a Latte’) to serve our staff and customers. This really helped with ambiance inside the store. On Fridays we started a program where we made lunch for the staff. Eventually this policy was extended to Saturdays as well. The team spirit of the shop, and customers too, was lifted to a higher level. I wanted to make R+E Cycles the best shop in the industry to work at. I’ve found that keeping employees is very efficient.

We teamed up with bicycle traveler Willie Weir to design and market (as a model) the bicycle we had built for him back in 1996. This helped boost our reputation as a travel bike company throughout the decade. Email sales really took off with the Willie Weir Adventure (our UTB) bicycle.

In 2005 we acquired Bushnell Cycle design, and hired Master Frame Builder Dennis Bushnell. We were able to patent his eccentric bottom bracket design, and grow the production and sales of the eccentric from just a few hundred each year to thousands. With Dennis came several established wholesale accounts that filled the frame and paint shops with frames to be shipped all over the country.

In 2006 we used our decades of bicycle fitting expertise to design a fully functional bicycle fitting system including software.

Next-fit™ was introduced in February 2006.

In 2006 we also re-tooled the frame shop to produce bicycles like no company has ever done before! This is a transformation that brought the price of our bicycles down to the price of bicycles produced overseas, while at the same time improving their quality. It was important to us that Rodriguez Bicycles become the best value in the bicycle industry. Without the efforts put forth in the winter of 2006 by the folks here at R+E Cycles we would either have to produce our bicycles overseas, or charge twice the price that we charge for them.

Back on Top!

Before long, Rodriguez Bicycle company (R+E Cycles) was back on top as a business leader in the Bicycle Industry. It wasn’t long before we started attracting the attention of business publications like the Puget Sound Business Journal. Here is their front page article about our effective production of bicycles in the United States. Lance Armstrong had made cycling popular again, and off we went! Like Lance himself, we accelerated in the industry. We expanded our high-end road bike offerings to include some of the lightest road and tandem bikes in the industry.

We couldn’t let Angel’s efforts be for nothing by letting Seattle’s first ‘on-street’ bike parking area go to waste. Through this decade, we worked with the city (it took several years) to give our ‘on-street’ bike parking area a complete overhaul. We got a new heavy duty bike rack (ironically shaped like a car), fresh paint and new respect for how hard Angel must’ve worked to get the project done in the first place. Here’s what the shop looks like now.

2012 To the Future, and Beyond!

2012 Staff Photo

My name is

Dan Towle and 2012 is my 19th year as the owner of Rodriguez Bicycles (R+E Cycles). That’s two years longer than Angel owned the company! While writing this page for the site, I realized: things that seemed like they happened yesterday actually occurred decades ago. I had to do the math to believe 19 years (in 2012)!

Rodriguez Bicycle Company remains a Seattle cycling institution as well as a leader in the cycling industry. We have persevered through some of the worst times, and pioneered in the areas of bicycle fit and manufacturing for almost four decades now.

This year we have a fully redesigned website written in CSS. As I write this, the catalog is almost done and the new website just went live an hour ago. We’re teaming up with Glenn Erickson (yes the same Glenn Erickson) to offer Erickson Custom bicycles, thus putting the E back in R+E for 2012. We’re very excited to offer all of the innovative products that we make here, and hope that you choose us as your bicycle company.

This is a historical tour, so let me get historical here. When you choose to buy a bicycle, you are actually choosing to buy the staff of that shop. This is the best staff in the history of R+E Cycles, and I think the entire industry. Everyone here has been here a long time now, and this is their career of choice. If you want a bicycle, there is no better time or place than Rodriguez Bicycle Company right now.

This article is from 2012. To read an updated version, Click Here.

(2meg).

(2meg).