In our industry, products from the past seem to re-appear quite often. Bicycle disc brakes are one such item. Like a Phoenix, they’ve risen from the ashes a 3rd time in just the last 40 years. Since their acceptance as

Article Overview

In our industry, products from the past seem to re-appear quite often. Bicycle disc brakes are one such item. Like a Phoenix, they’ve risen from the ashes a 3rd time in just the last 40 years. Since their acceptance as a superior brake for the mountain bike, it seems that more and more people are asking about them for their road bikes. Most manufacturers are happy to just slap them on, but is there more to consider? Are they better for every type of bike and every type of riding? Let’s follow the history a bit, and see.

This article is for those who want to learn more about bicycle disc brakes. It’s not to convince the reader that disc brakes are good or bad. My purpose is to let you all know that disc brakes have been around a long time in our industry, and there are upsides and downsides to them. We’ve built hundreds of frames over the last 40 years that are designed for disc brakes (over 100 in 2012 alone). We also run one of the largest bicycle facilities in Seattle (since 1973) and we service disc brakes of all types on a daily basis. We have more history and experience than most to draw from. So, if you’re ready to separate the fact from the fiction, put on your dancin’ shoes and boogie, this is the article for you.

Disco Fever

November, 2012

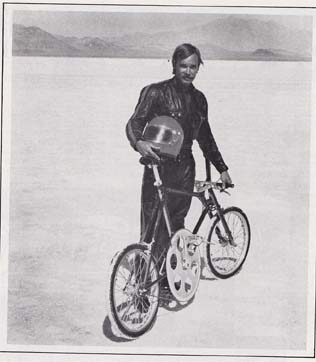

It was the 1970’s! The BeeGees were ‘Jive Talkin’ all over the music charts, and all the kids wanted to be Vinnie Barbarino (Welcome Back Kotter). I was the resident bicycle kid in my Junior High class, and I rode my Raleigh Rampar all over the area all of the time. So, imagine my surprise when my buddy Barrett showed up at school on a new ride…..one with all the candy! He was excited to show me his new bike, but class was about to start and we didn’t have time to go back outside and look at it. I got a quick verbal description (including hand motions) painting a vivid picture of this futuristic 10-speed. “It has numbers on the gear shifters to tell you which gear it’s in….like a car!” he said as he motioned the international ‘stick shift’ hand signal that all boys of my generation understood. “But, that’s not all! My bike has disc brakes like a car!” Could it be? I thought. Disc brakes on a bicycle? Wow! How cool is that?

What Barrett had purchased was a Western Flyer 10-speed at the local auto parts store (Western Auto) in our small town. After school, we looked at his bike together, and he did indeed have a bike with all of those features.

As it turned out, in 1975, Shimano actually had just released 2 versions of disc brakes for bicycles. One hydraulic, and one cable-actuated. Here’s the page from the 1975 Shimano catalog showing both types of Shimano bicycle disc brakes.

Note:

I know a lot of people, even people in the bicycle industry, think that bicycle disc brakes weren’t even invented until the 1990’s. There are probably older versions of bicycle disc brakes, but from my historical perspective, life began in the 1970’s shortly after the invention of the wheel, so that’s as far back as I’m going to reach in this article.

Back to the story

Now, finding out that he had a Western Flyer eased my jealousy quite a bit (Western Flyers were just Huffies by another name). I proudly rode a Raleigh from a bike shop in a neighboring town (our small town had no bicycle shops).

As the 1970’s disco’ed on, so did the introduction of more and more bicycle disc brakes. Bridgestone, Japan’s largest bicycle company, introduced their new cable actuated disc brake, and Phil Wood came up with a super high-tech disc brake that we here at Rodriguez used on tandem bicycles.

Just a quick note: Some people think that we at Rodriguez bicycles are anti-disc brake. As you can see, we’ve used disc brakes on our bikes since the 1970’s. Most of our customers choose cantilever brakes for touring and tandem bikes because they like them better, not because we don’t offer them with disc brakes.

Good Money Gone Bad!

All that money spent on R&D, but the bicycle disc brake would die in the early 1980’s along with disco. Now, everyone knows that disco burned itself out, but why didn’t the disc brake stick as a bicycle component through the 1980’s?

A lot of people will say “Well, those old disc brakes didn’t work well” but those people would be wrong. They may not work well by comparison to disc brakes of today, but comparing them to rim brakes at that time, they worked great! The industry was behind them, and they spent tons of R&D cash to develop, manufacture and promote them. So, why didn’t they catch on? Eventually, the disc brake was sent to the scrap heap of ideas gone bad.

The ‘Road’ to Failure

In the 1970’s, every bike was a road bike. The fact was, even though disc brakes worked well, they were a lot heavier, and a bit noisy. Add to that the fact that they were harder to adjust, and parts (like pads) were hard to find at your local bike shop. For road bikes, rim brakes worked fine and they were lighter as well as less expensive, and any bike shop or sporting goods shop had pads in stock for them. In short, the benefits of the disc brake were outweighed by sacrifices….at least as far as road bikes and tandems of the 1970’s were concerned. The need for a disc brake really didn’t exist until the introduction of the mountain bike a decade later. Besides, we all needed to save our money for some new dancin’ threads.

The Metal Years

Fast forward to the late 1980’s. Disco is dead, Poison, Motley Crue, and other bad boys (that looked like girls) topped the charts, and a few high-end mountain bike companies are looking for brakes that will work even if the rims are bent and covered in mud! I know! How about disc brakes? Yes, the disc brake is resurrected in the late 1980’s by a few high-end mountain bike companies.

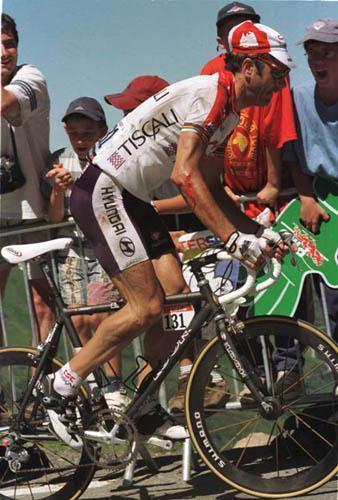

Now, one would expect to see the Bridgestone, Shimano and Phil Wood discs simply re-appear…..right? Well that’s not how we do things in the bike industry. Even though these would’ve been great starting points, we started again, re-inventing the same designs that used to exist. Here’s an example of a 1980’s mountain bike with a set of Suspenders hydraulic/cable disc brakes. There were a few different high-end disc brakes in the late 80’s. Most of them were expensive and difficult to adjust. Some of them worked alright, but some didn’t really cut the mustard. Shimano put out the V-brake (yuck!) somewhere in the early 1990’s, and that really became the brake of choice for most mainstream mountain bike customers. Only the really high-end specialty mountain bike ran disc brakes…

A quick deviation into the 1990’s tandem world

As is custom in the bicycle industry, tandem builders tend to think that something made for a mountain bike will work great on a tandem. Don’t ask me why, but for some reason there are people that see a correlation between a 180 pound guy trying to stop while riding through a muddy stream at 20mph, and a 350 pound tandem team trying to stop while screaming down a mountain pass at over 60mph on asphalt. I fail to see the similarities, but none-the-less, as high-end mountain bikes started using disc brakes in the 1990’s, tandem people requested them on a regular basis. Here at Rodriguez, we used a lot of the Hope disc brakes in the 1990’s on tandems. We only used them as an auxiliary brake, and never as a primary brake. As a matter of fact, I still have 2 of these brakes sitting here beside my desk as I type this. I can tell you many stories of mythical tandem disc brakes (sometimes resulting in very aggravated customers), but suffice it to say that this brake was not at all capable of stopping a tandem, just slowing it down.

The point of this deviation is: Mountain bikes use disc brakes not because they work better, but because they work better on mountain bikes.

..So, as a high-end mountain bike brake, the disc brake limped along through the 1990’s, but never took off as a standard to be used as primary brakes on tandems or touring bikes. Really, that’s not what they were designed for, so that makes sense right?

Home Sweet Home

The disc brake finds its home in the new millennium

Benefits Galore! To the mountain biker, the disc brake is a gift from above. Now the off-road rider could bash his/her rims completely out of true and their brakes don’t rub. They can ride through a muddy stream and their brakes don’t clog up. They don’t have to worry about sand and grime all over their rims getting trapped in their brake pads and damaging their rims. The mountain biker is willing to trade the noise and extra weight for these benefits. Noise doesn’t matter much because off road riding is pretty noisy anyway.

As companies embraced the disc brake, lower cost versions of cable actuated disc brakes developed and the V-brake could finally all but disappear from the industry. Not soon enough I say…the V-brake was the worst of both worlds really, but that’s a whole different article.

Now we see almost all mountain bikes with disc brakes (as we should) and we see the tandem and road bike companies offering them as well. We offer disc brakes on any bike we make. The question often asked of us is “why not use disc brakes on all bikes?” Believe me, it would be easier for us to just use disc brakes on all bikes and tell people the same thing that are reading in the magazines…..ie. that disc brakes solve all your problems and are the perfect solution for every type of riding. We do have an obligation to the truth though, and the truth is that there are certain applications where a disc brake is preferable, and certain applications where they are not the best choice.

The theory goes “If they work better on a mountain bike, won’t they work better on a road bike or tandem as well?” Gee…where have I heard that logic before?

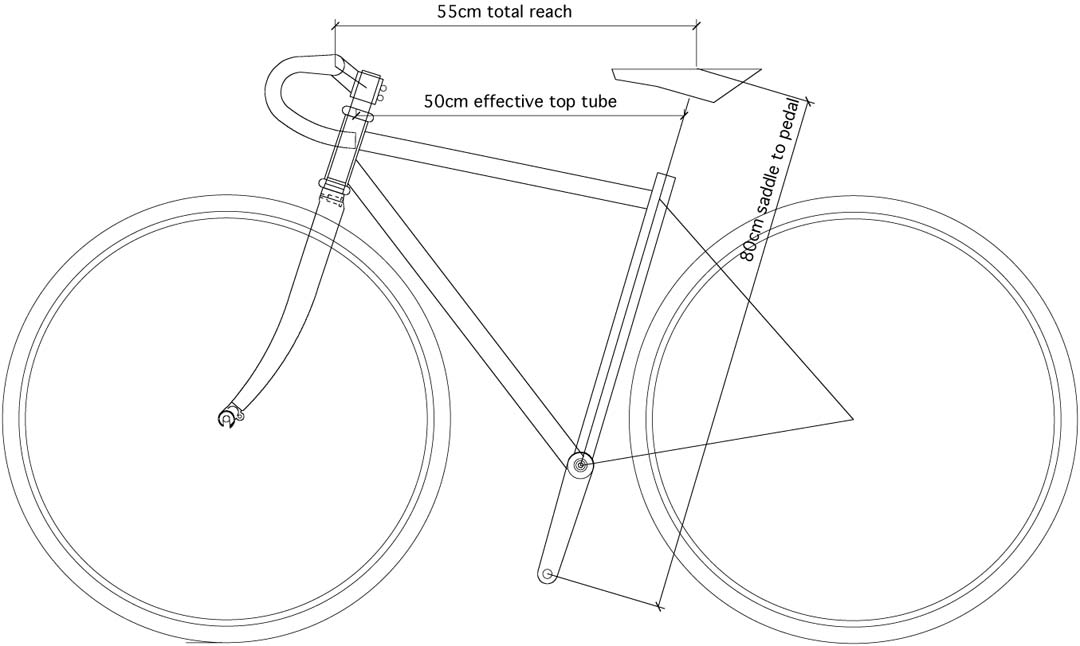

One size does NOT fit all

In reality, there are applications that are better suited for disc brakes and there are applications that call for traditional brakes. When you think about it, all bicycle brakes are disc brakes. A disc brake uses a disc brake caliper attached to the frame to grasp a spinning disc (rotor) attached to the hub. A traditional brake is a caliper that uses the rim (also a spinning disc attached to the hub) in place of the rotor. This eliminates the need for the second spinning disc (rotor). I’ve got an anecdote about this theory if you want to take a break from this article. There are benefits and drawbacks to disc or traditional depending on your riding conditions and desires.

It’s Important to Be Careful

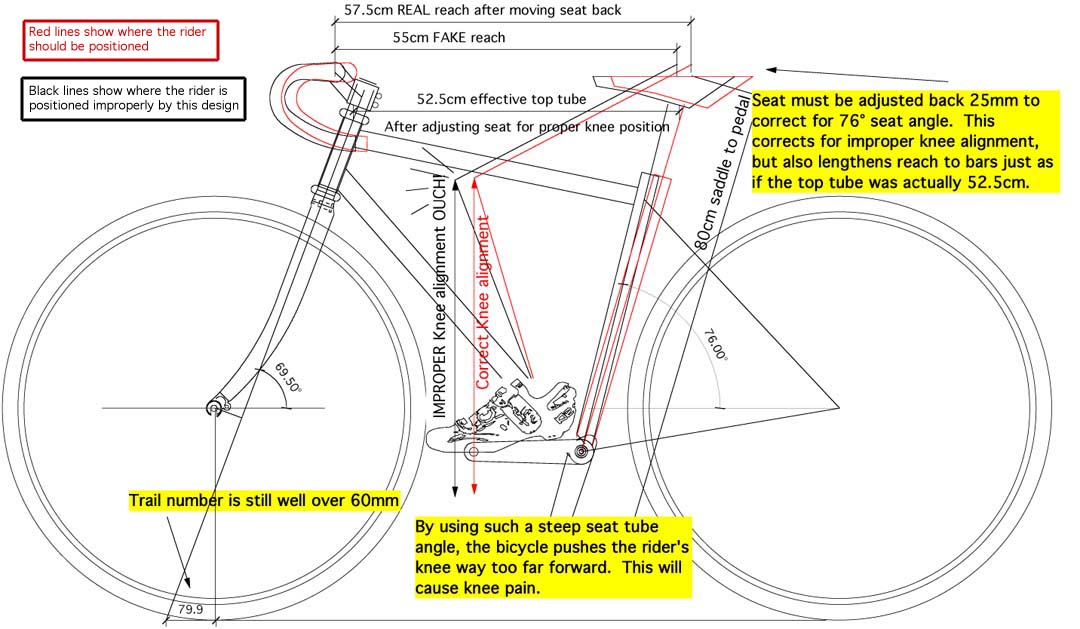

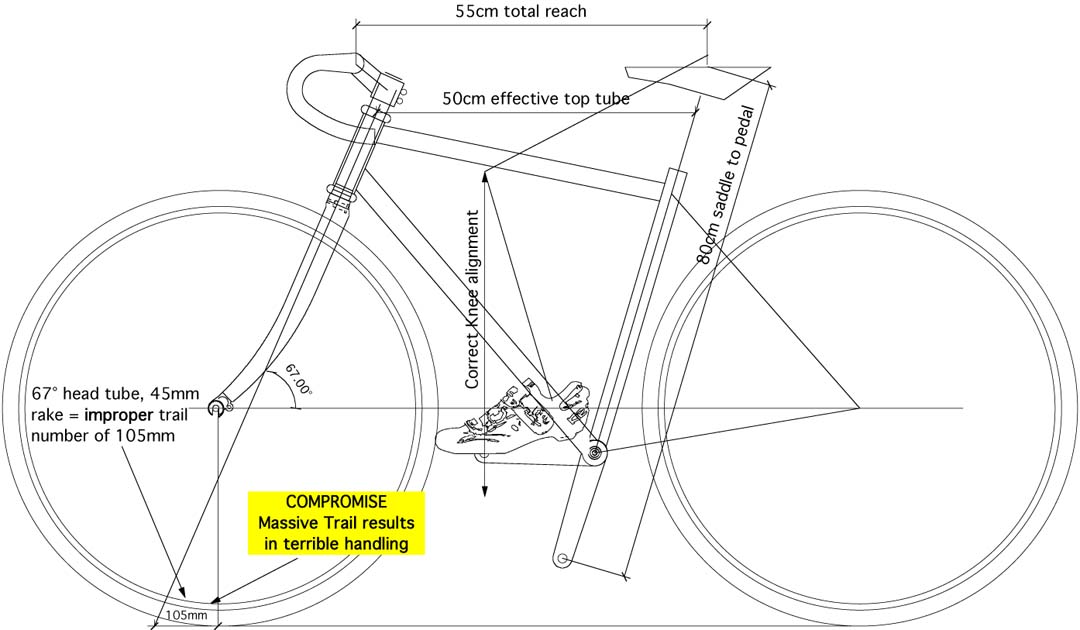

Improper assumptions by you, a bicycle manufacturer, or a bike shop can result in serious injury or even death. Want some proof? Here it is.

What should I do?

We’ve come full circle with the disc design, and they look a lot like those 1975 Shimano brakes don’t they? There are very good cable actuated and hydraulic disc brakes. Even so, the benefits and drawbacks remain the same as they did in the 1970’s. Nothing’s changed in terms of road bike uses. The mountain bike brought on a whole new style of riding and with it, many innovations that wouldn’t have come around otherwise. The disc brake is proof of that. The mountain bike brought the disc brake back from the dead, and it’s the perfect application for it.

Controversy where there should be none

I had some reservations about even writing this article, and I’ve put it off for a couple of years. I’ve actually had some people get mad at the fact that we see any downside at all to the road bike disc brake. It seems that over the last few years, magazines and blogs have been buzzing with glowing reviews about road bike disc brakes and one who dares to suggest that there is anything but perfection in the design is labeled a ‘retro-grouch’ and shunned. Well, maybe shunned is too strong of a word, but there have been occasions when I’ve had discussions with folks who seem to get angry at the fact that most of our road bike customers prefer a rim brake.

Here’s a quick story about one such occasion.

As it turns out, paper doesn’t refuse ink, keyboards don’t refuse fingers, and the internet doesn’t refuse opinions of those who have vested interets. Its up to those who have decades of experience building and servicing bicycles to bring the facts to the surface (facts are stubborn things).

I decided to go ahead and write the article though, and I hope I’ve done so in such a way as to not offend the true believers. Being the kind of shop we are, we won’t try to push you into one style of brake or another. Instead, we’ll just put together a list of the benefits and compromises attached to each type of brake and you can decide yourself which brake suits your style of riding and budget. Without further ado, ladies and gentlemen: Behold…The List!

The Upside of disc brakes:

- Work the same if your rim is straight or if it’s bent

- Shops with very young mechanics know how to work on disc brakes (not so much with rim brakes)

- Work better if you’re riding through a stream

- People will say “Cool! Disc brakes!”

The Downside of disc brakes:

- Disc brakes can be noisy. Not a problem off road, but on a quiet road ride the constant scraping sound drives me nuts.

- The bike equipped with disc brakes will weigh 1 ~ 2.25 pounds more than rim brake version of the same bike

- Hard to find brake pads or rotors if you’re touring in remote areas (make sure to carry spare pads and rotors)

- Hard to tell what brake pad wear is

- Can suffer from ‘hard to diagnose’ inconsistent performance

- If your bike is a travel-bike, the disc brakes make packing and un-packing much more difficult

The Upside of rim brakes:

- Quiet

- Lighter weight frame, fork and wheels can be used (save up to 2.25 pounds)

- Lower cost. ($200 ~ $500 less)

- Longer pad wear and lots of pad options available

- Replacement pads are cheap, available everywhere, and last longer than disc pads

- Pads are relatively easy to replace

The Downside of rim brakes

- Younger, inexperienced mechanics may get ‘creative’ while adjusting your brakes.

- Rub the wheel if you break a spoke or bend your rim

- Poorly maintained, can wear out your rim prematurely

- Don’t work if you’re riding through a stream

- People will say “Why didn’t you get disc brakes?”

Thanks for reading,

– Dan

Over the last 8 years or so, we’ve seen a lot of interest in internally geared rear hubs (IGH for short). A bike with an IGH has all of the gears housed inside the rear hub instead of using traditional cogs, derailleurs and chain rings. Remember your old 3-speed (or your parent’s old 3-speed)? It’s like that, but with a lot more gears. IGH technology is an old one (over 100 years old actually), but with the invention of derailleurs, the 3-sp IGH was abandoned by most cyclists for the unlimited gearing options of the derailleur. I don’t see the end of derailleurs anytime soon, but for those who are investigating IGH, we’re trying to help you with your homework.

Over the last 8 years or so, we’ve seen a lot of interest in internally geared rear hubs (IGH for short). A bike with an IGH has all of the gears housed inside the rear hub instead of using traditional cogs, derailleurs and chain rings. Remember your old 3-speed (or your parent’s old 3-speed)? It’s like that, but with a lot more gears. IGH technology is an old one (over 100 years old actually), but with the invention of derailleurs, the 3-sp IGH was abandoned by most cyclists for the unlimited gearing options of the derailleur. I don’t see the end of derailleurs anytime soon, but for those who are investigating IGH, we’re trying to help you with your homework. Last year, Shimano introduced their first serious entry into the field of IGH touring hubs, the Alfine 11. Now that Shimano is making a run at the high-end IGH market, that has spawned a lot (and I do mean A LOT) of IGH questions from around the world. People (as well as us) were hoping that the new Shimano hub would give them Rohloff performance at Shimano prices. As a major Rohloff builder, a lot of those questions have come to us.

Last year, Shimano introduced their first serious entry into the field of IGH touring hubs, the Alfine 11. Now that Shimano is making a run at the high-end IGH market, that has spawned a lot (and I do mean A LOT) of IGH questions from around the world. People (as well as us) were hoping that the new Shimano hub would give them Rohloff performance at Shimano prices. As a major Rohloff builder, a lot of those questions have come to us.