Puget Sound Business Journal (Seattle)

September 15, 2006 by Justin Matlick Staff Writer

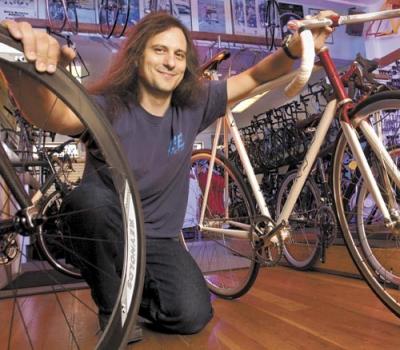

Likes Bikes

R&E Cycles, located at 5627 University Way NE in Seattle, is owned by Dan Towle, above

Photo: Dan Schlatter

Dan Towle has turned R&E Cycles into a leader in custom bicycle production

Since taking over R&E Cycles 13 years ago, Dan Towle has increased the bicycle manufacturing company's production by more than 500 percent, boosted revenues, and re-engineered its Seattle production facility. Along the way, he has grappled with a question familiar to many small business owners: How do you expand your business and still maintain top-notch quality?His answer: Keep it local. While most of R&E's competitors now manufacture their products offshore, R&E's bikes are still made by hand in Seattle's University District. According to Towle, keeping production close to home allows the company to maintain strict quality controls, as well as the flexibility to modify each of the frames it builds.

"You simply can't accomplish that in Taiwan -- you have to compromise somewhere along the line," Towle said. "I know because I've built parts there." Towle, who has "had a love for bicycles as long as I can remember," started translating that passion into a profession when he was just 8 years old. His father owned a service station in a small Idaho town and Towle took charge of all the shop's bicycle repairs.

"It was the only gas station in town, and that's where all the kids brought their bikes to get fixed," he said.

Towle stayed close to the cycling industry and after moving to Seattle, went to work in R&E's shop in 1987. At the time, the company operated a retail store where it sold major brands such as Trek and Specialized, and also built around 50 custom bikes a year. Those bikes, which were branded "Rodriguez" after company founder Angel Rodriguez, were tailor-made to fit the needs and physiques of individual customers.

Rodriguez sold R&E not long after Towle arrived and, after the company foundered under new ownership, Towle bought it in 1993. Almost immediately he set his sights on expanding the Rodriguez brand.

His main reason for the expansion: Most bike makers manufactured only a limited number of frame sizes, and many riders found themselves forced onto frames that were uncomfortable because they didn't fit.

"It was getting harder and harder to get people to fit bikes that we weren't making," Towle said. So, in addition to the Rodriguez custom bikes, Towle decided to produce standardized bikes that would fit people who he thought were poorly served by the industry. He started by manufacturing three small sizes designed to fit women less than 5 feet 3 inches tall, and initially decided to build a test batch of 30 frames.

"We sold all 30 before we even built the first one," Towle said.

Buoyed by this response, R&E gradually developed a full line of bicycles. They now come in 15 sizes and include 10 different models, ranging from a $1,900 road bike to a $3,400 "ultimate travel bike," which can be broken down and loaded into a suitcase. R&E now sells approximately 300 of its production bikes a year, plus about 50 custom bikes, Towle said.

An R&E Cycles bicycle shirt and team photo, both from the 1980's

Photo: Dan Schlatter

"A lot of people spend $2,000 or $3,000 on bikes that fit them terribly," he said. To be sure that R&E's customers don't have the same problem, the company has developed a multistep fitting process that starts with R&E employees taking down customers' measurements, including inseam and arm length, and feeding the data into a proprietary software program. After the software estimates which sizes will fit best, the rider is seated on an adjustable stationary bike, which employees modify until the rider feels comfortable. Data from that bike is then fed back into the software, which gives a final size recommendation. "We can fit just about everybody like a glove," Towle said.

The bikes have been a hit among cyclists ranging from triathletes to retirees gearing up for international bike tours, according to Towle. Also, Towle said R&E has a dedicated following among people who commute to work on their bikes, adding that riding to work is becoming increasingly popular.

"With the high fuel prices, we're definitely seeing more commuters," he said. Thanks to the popularity of its Rodriguez bikes, the company's store has stopped carrying most other brands, Towle said, and R&E's annual revenues now consistently top $1 million, with about 25 percent of those coming from R&E's on-site repair shop.

However, transitioning from a custom builder to a larger-scale producer has brought the company some problems. For instance, in the past, R&E customers have sometimes had to wait two or three months for the company to deliver their bikes. The reason: Its manufacturing facility was configured to churn out only one size of bike each month. This created problems when inventories ran low, because customers then had to wait for the factory to make a batch of the size they needed. So Towle set out to find a way to reduce wait times by making production more nimble.

"We had to figure out how to manufacture bikes one at a time, because that's how our customers come in -- one customer can come in at 6-foot-8, while the next one is 5-foot-3." Last winter, R&E completely reconfigured its production with this goal in mind. "I pulled the plug on Nov. 26, and we tore the frame shop completely apart," Towle said.

The end result: a facility that can build 600 bikes a year, up from around 250, and fill most customer orders within two weeks.

While popular bike makers like San Francisco-based Soma Fabrications now make their frames overseas, Towle said it would be impossible for R&E to accomplish its goals with overseas production. Towle, who has had individual parts built in Taiwan, said Taiwanese manufacturers charge a steep fee to set up their equipment for each part they make, which gives companies an incentive to minimize the number of frame sizes they build. "I would have to compromise and combine three sizes into one," he said.

According to Towle, that would hinder R&E's ability to provide customers with a good fit -- and also rob them of what he sees as another core benefit of local production. "You can come down to our shop, shake hands with the guy who is going to build your frame, and feel like you're part of something," he said.

Contact: jmatlick@bizjournals.com - 206-447-8505x158